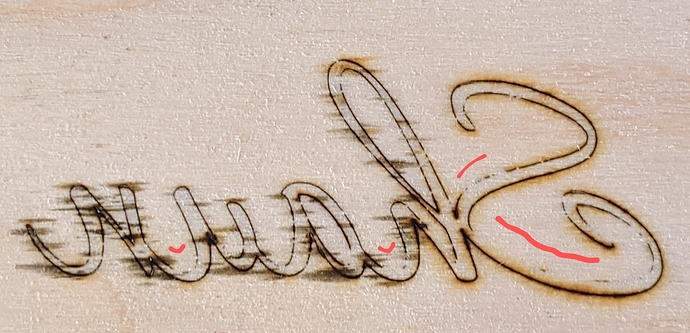

So, I have a question about laser cutting. I recently added a 40 watt aquarium air compressor to my 2.3 watt laser setup. using some silicone tubing with an 0.8mm 3d printing nozzle on the end, and it’s seemed to make a big difference in my cutting, I still seem to struggle with small sections that arent cutting.

pic of underside

7 passes, 0.43mm per step, 3.5mm/s , laser is 70mm from material surface, focused.

there is a steel plate below the work material, resting directly against it. would this negatively affect the cut?

should there be space below the material? I’m wondering if the steel plate is ‘sinking’ the heat somehow?

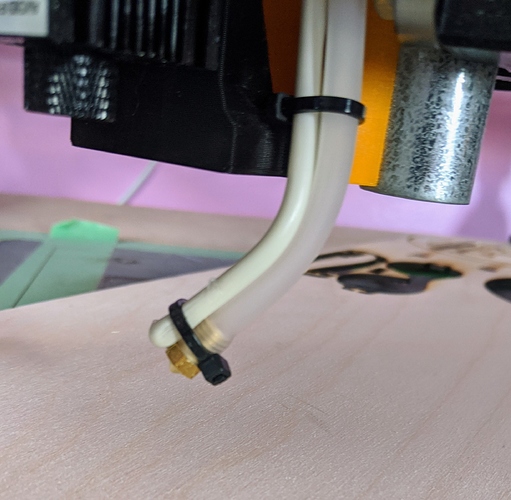

here’s a pic of my air output. it’s zip tied to a bent 10awg copper wire which is scewed to the universal mount, aimed directly where the laser is