The z-axis goes down quickly when the power is turned off. When the spindle is in the middle, it can hold it for a while.

If you turn off the power at home (z200), only the left side comes down quickly.

Is this normal condition caused by weight or is there a problem that I made a mistake?

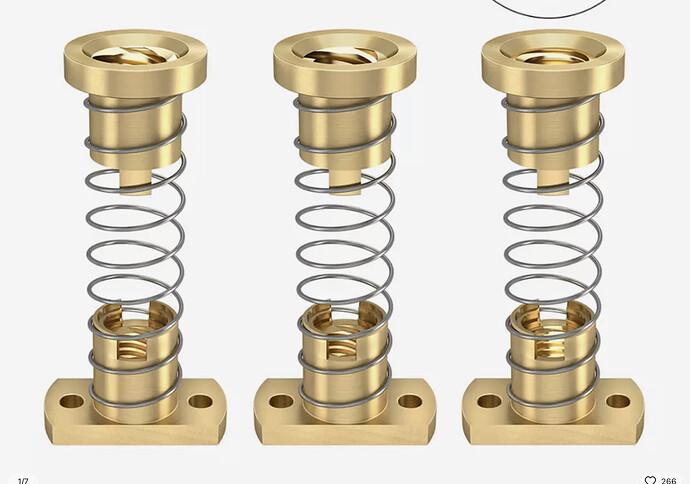

I saw someone’s post and they used something called Leadscrew Parking Stop Block, is that the best way?

This is normal, and good sign you precisely built a well fitting/oiled machine.

This normal behavior isn’t ideal though. Especially if unexpected reset/situation occurs.

I like the Z Axis Parking Blocks, useful when a controlled power off happens, and/or when dismantling and storing away.

Not an opinion, just an observation… have seen some people switch to leadscrews with 1 start, or better balanced but more expensive 2 starts. 4 start leadscrews were chosen and recommended for different reasons, for details see Time to upgrade from threaded rod - #7 by EdNiedziejko Topic is focused on MPCNC, but the pros/cons apply to LR as well.

Ensuring post job scripts move to a safe location away from your work piece seems to be recommended. If your jobs are not regularly fully utilizing y axis, could additionally leave some blocking at max Y for gantry to fall onto, rather than smashing bit into spoil board.

Curious if anyone’s come up with other solutions? Personally contemplated a latching solenoid ‘parking brake’, just on x min side. E.g 3d printed handle grub attached to top of leadscrew, solenoid on YZ plate. But there’s probably a simpler easier way… Haven’t tried, but maybe switching to 2 start would be easier, simpler and good enough, depending on what’s being cut/carved.

Off topic… Maybe, Parking brake, or more generally a “z lock” on both x min and x max, could potentially double up to help provide a mechanically assisted way to lock z-axis at specific height during a cut. Requires post processor to inject lock/unlock gcode. Just an idea…

It’s the same design concept as the lr2.

I’ve used parking stops successfully on the lr2:

- use a macro and machine coordinates to park the gantry back at the starting point when done all work

- manually place parking stops

- run another macro that lowers gantry to a mm above the stops

- shut off power

In an emergency unless there’s some kind of “open when on” z lock the gantry will sink when power goes.

An emergency stop that could stop the router and movement commands mid execution but keep power to steppers would be really handy ![]()

Those nuts just cause a lot more friction. If you really can’t live with parking it before disabling the motors, you can use a 1-start leadscrew. But you will sacrifice top Z speed. The motors have to move 4x faster and steppers don’t work as well at high speed.