This is proof it cuts on my g code however it also shows inconsistent depths as the z axis fails under its own weight as it only dose it the end the spindle is as it’s too heavy for the motor.

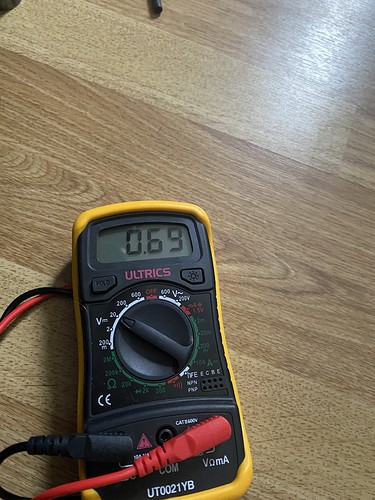

Please just use the crown, after you set the drivers to under 0.7V.

That picture is not proof of anything except it is not doing what you want it to do.

Yes because the motor failed that’s why one is cut through the one beside it is shallow and the other is deeper

Charlie, please just try it. If you can’t try it I really can not help you. It is the weekend I am not working so please either try it or just get back to me when you do.

The test crown (the premade gcode, not you doing cam on it yourself) is a proven conservative test for us. It takes just a few minutes and if it fails on the TC, then we know nothing we do in the gcode, or estlcam settings is going to fix anything. It really is a quick sanity check to split the problem space down by about a third.

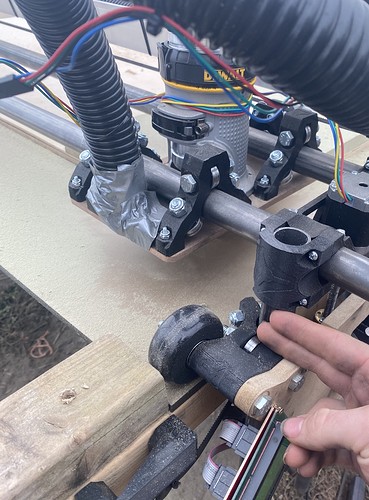

How do you have the Z wired? Is it in serial or dual? Parallel will cause this, easily.

The other very common issue is the max Z speeds. Did you use firmware from MarlinBuilder releases?

After that, we can look at the mechanical stuff, or how you are sending it, or the grub screws on the couplers or take another look at the wiring.

I know it is hard to be told to do something you don’t think will help, but we wouldn’t suggest it if it wasn’t in your best interest. We are on the same team here.

![]()

To the OP: Keep working through the issues. The end result is well worth the effort.

I’ve ran the crown it cut the correct shape however the machine still dropped and worked it’s way out of square over the program at his lead to it cutting through the crown drivers where adjusted and everything worked fine I think I have a faulty stepper on my z axis as I connected them following the instructions and had the correct v1 looms for the kit it only drops when th z axis engages to move up or down and only on 1 side could you confirm if the stepper may be the issue

Thank you for testing that. It looks like it is a bit small. Are you using a larger bit than 1/8"? Did you use the premade gcode or do the CAM yourself?

I think I have seen one stepper be bad on these forums and I have posted 15k posts. Steppers are super simple and most of the time people think it is a bad stepper, it is either the wires, or the motor shaft is skipping in the coupler.

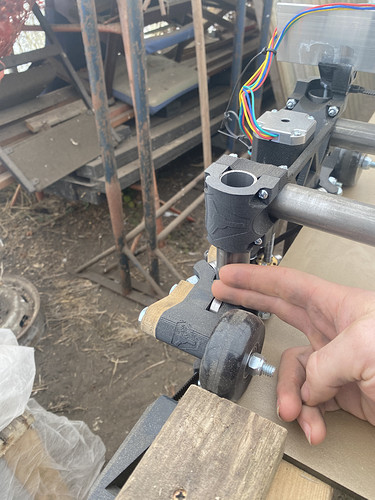

Can you share some pics of the electronics?

Does the Z fall on its own when you turn it off?

I used the pre made gcode and all I had to hand was an 1/8 inch the machine will drop when the powers off it just seemed to drop whenever the motor either in gaged or disingages I can’t picture the board atm as it’s at my workshop my setup had all the v1 parts as I bought a kit the motors all spin correctly and worked fine when I did a test run before mounting it to the table and it only dose it when it’s under its Owen weight and has dropped and gone staraight through the work pice spoil board and table previously

I’ve also checked the motor to screw connection and all grub screws are tight so it’s not slipping in that sense

Just throwing some things out there that I ran into:

My Z got messed up similar to this when I first started running it from cncjs because it was driving it too fast. Had to limit the speed as was suggested in the forums.

Also my wiring connections worked themselves loose during setup and caused flaky steps until I replaced the pins in the connectors.

The other thing I’d be curious about is the size of the gantry. I’m using thicker steel tubing over a 4’ span and if the router is all the way up against one side, it is sometimes too heavy and misses steps on that side. I’m planning on switching to 2mm lead screws to address this, as I really want to add the weight of the aluminum square tube XZ main parts described by Rich in Upgrades on Stiffness. I’d try cutting in the middle of the machine rather than the edges to see if there’s any difference in behavior.

V1 doesn’t sell ramps with drv8825s.

Did you buy the wiring harness from V1?

I had to change to ramps at my own expense as the Rambo I bought with their was faulty it started up with the marlin then went to a blank lit screen all connections where fine something went wrong

Have you reflashed it?

No I haven’t as ramps seemed an easier solution

Well it can be easy. There are two options. Platform io or xloader.

You can already flash your ramps so flashing the rambo is no harder.

Our ready to go firmware is here, and it sets the driver current even https://docs.v1engineering.com/electronics/marlin-firmware/

We have worked very hard to make all of this as easy as possible and there are a couple of really smart people here to help. Please be sure to answer any question asked of you to make it easier and keep everyone interested in helping.