Just a shot in the dark, but maybe try removing the ‘&’ in the file name. I know it’s supported sometimes, but could be causing a problem

Do you think I will need to re-tool the whole design? Meaning, set up the cuts on the design again?

Good point. I do that as well!

I don’t think so, if you open your design file(.e10), then make sure to import the settings file I sent, I think it will be ready.

The.e10 file does contain settings as well so anytime you open it it will revert things so you will need to open it, then import my settings, then SAVE a new .e10 so the new settings are saved. That has bitten me before, opening an old file changed settings.

Watch your tools feeds and speeds and make sure they do not change.

That was a better round. But I still missed something…

Might help if I attach the probe. But it does look as though it is attempting to do it, as opposed to giving my an error code. One more homing and try again…

Standby

Screen shots of the terminal window will help us figure it out real quick

My code will immediately pause, wait for you to hit resume, then probe Z, then pause again wait for a resume, then cut.

You can not run my config without a touchprobe.

Yes, thank you, that worked a trick! Now with the Jackpot, 5 stops and homing, your start up code - with the probe - I think I can get back to enjoying this!

Again, Ryan, you are great! And also @Michael_Melancon

@Britt

@pajarojo

thanks for the support gents!

Heck yeah!

I know I am biased but I am already using the CNC more with the Jackpot. For some reason it is far easier for me than the LCD. Instead of getting out my table saw for 15 squares I loaded up the CNC let it cut them while I was helping you get going. I used to think the tables saw was faster…I think I was wrong.

I think you’re right. I’ve got a decent little woodshop with a sturdy cabinet table saw, a router table, planer, etc. But this Jackpot combined with the LR3 is a full game changer! You’ve truly outdone your community by thinking and rethinking how this should go.

The Jackpot really hold those motors in to make tools changes a super breeze! Combined with the spindle holder on the X - well, pure ease of mind! as long as it continues to go well. Technology is great until it’s not. Most of that “It’s Not” can be user issues.

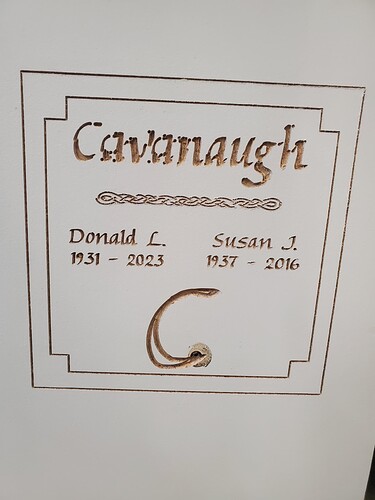

But as I was typing this out, I noticed my small sign engraving I was doing just uncalibrated for no reason. I’m using the 45 degree V bit .125" from V1E, but the tool is poking holes in the material in odd spots, then taking my 5 lines and getting the alignment all jacked up. The only code I changed from the test to final was depth and width of cuts. I didn’t adjust alignment to the design. Here’s the pictures of the test on white and final on purple heart.

I am concerned as to why the router makes heavy pokes that don’t jive with the design.

My X belt is nice and tight.

My Y could use maybe a touch of tensioning. A little slack and such could be explained, but it’s almost 20mm off on the final.

This is all a CAM issue at this point.

V bit are heavy cuts, the middle gets dragged while only the edges do much cutting all at different surface speeds.

Working in one material and not in another sounds like you went to aggressive.

Not sure about the Z axis pokes.

For a Vbit that is everything but feedrate. Depth is obvious but width can leave lines instead of clearing a section if it gets a flat bottom. This could explain your depth of cut/z poke.

I suggest looking at your gcode with a gcode visualizer. https://ncviewer.com/

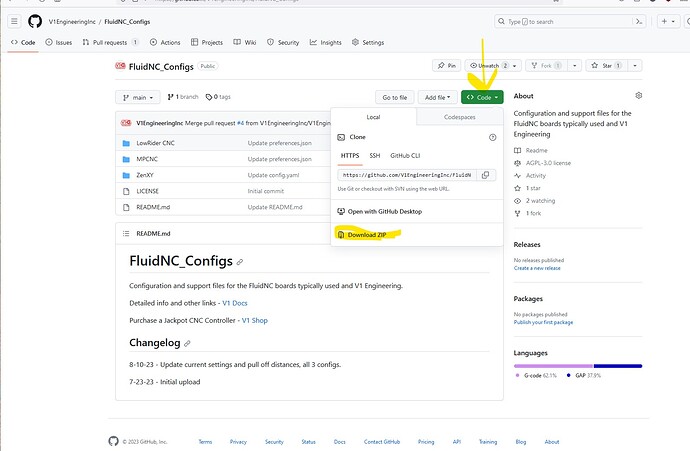

Well actually on that note have you seen the new yaml and preferences files I put up for the jackpot board the other day. Those might actually help a bit. Just upload them to the board and restart.

Back at it again this weekend. What a long week away from the shop! Work, it’s a thing.

So I am working on updating to the latest yaml and I found the git-hub repository, and associated files. Not certain how to download these at first glance at least. But I thought I would use the USB connected tool as mentioned in the docs but whenever I try to use connect, it can never find the Jackpot.

I am using chrome. I’ve even looked to see if I can add the board like a printer in my windows (64bit) device settings.

I figure to give up on the USB connection and try to update over the WiFi - which means I ought to download the yaml files and have them at the ready… oh, back to not knowing how to download off github… I did find how to download the “Raw” file, I assume this is what I need. So I’ll try that. But in reality, it would be nice to learn how to connect via USB line so I can use the browser connect tool.

Those stabs being taken at the material look to me like the contours were not properly closed or that there were tiny fragments of a drawing that are being done as well. Had that happen to me before.

It should just show up in device manager, if not the driver is linked in the instructions.

What version of windows?

I forgot, last time I attempted to connect via USB it couldn’t find the com to connect. It attempted COM4 and COM3 serial ports but to no avail. I’m in a terrible cycle here. Not getting solid carving and not a way to connect to the Jackpot. I’m thinking I will need to return to the old Archim board to complete this build - I’m running out of time. I can’t play with this much longer.

Did you use the driver I linked in the instructions for connecting to a PC?

Also lets step back a bit here. Do you have any issues with the test crown? Are we sure you just don’t have a bad gcode file? Can you link it to make sure you have made all the changes need for GRBL from Marlin.

Are you not able to connect to it over wifi from your computer? You don’t need USB.