It looks square on the outside will it be bent on the inside like the crying room?

Is this gonna be your new workshop?

Man, I wish people here would build more timber-framed buildings, instead of doing everything in concrete. It’s such an ecological disaster and super slow, and each house is set in stone, meaning you can’t really change anything without breaking out the big boy tools.

Concrete lasts longer if you keep up with maintenance.

Yes, but there’s lots of other stuff to consider than only the longevity of a building in terms of its materials.

For instance, the realistic, statistical lifetime of a single family house here in Central Europe is currently about 25 years, not because its materials wouldn’t make it any longer, but simply because a newer generation of house buyers enters the market that don’t necessarily have the same taste or needs than the pervious one.

Since concrete buildings aren’t really adaptable or flexible, most houses are simply demolished to erect new ones.

Also wood is far less ecologically problematic than concrete which consumes lots of energy and emits huge amounts of CO2 to be produced - the cement part that is -, and devours even more energy to be seriously recycled.

Furthermore, modern facades are not simply concrete walls but oftentimes thermal insulation composite systems, which are a disaster for recycling, since the insulation is glued on.

Building in wood is 100 times easier when you do it yourself. I don’t think anyone uses concrete when people are doing the building themselves here in Norway. Concrete is mostly used for foundation work, oven pipes and such. This building is from 1946, and it stays straight and water tight.

We are expanding with an entrance hallway(with a breaker box for the electrics) and a bathroom. We are doing in the same proportions as the main building, to keep some harmony and keep it in the same style. We want to keep the architectural style to honor the buildings history and the historical value it keeps for the locals. It’s also a nice style in itself, that we want to build upon.

The bedrooms are in the attic, that was a dark attic earlier.

What is a crying room??? ![]()

I WISH! The plan originally was to build a separate workshop, that we could use as a base for all the rest of the renovation process. But alas, we need a water toilet, the outhouse is putting strains on the family, and I kind of agree. But that means that we have to wait yet a year for the workshop…

In the past, it was a room in spaces that were visited by the public (church, cinema, etc.) where parents were expected to take their infants, if they cried or threw tantrums.

Do you mean a regular toilet?

Daaamnnnnn. ![]()

We do our crying in the main living room

Yes, we are getting a regular toilet. We are all very much looking forward to that, so much that I can gladly wait with the workshop. Furthermore, I can’t expect to have to workshop to myself, my wife is found of working with yarn, dyeing and such, so we’ll have to share…

Sorry my memory was off to long ago.

“- “the whining shed” - the little buildning where dad can go and feel sorry for himself and play with his toys.”

Looks to be a great addition

Aaah, the sulking-shed! The whole cabin is a sulking-shed, honestly- for the whole family. The only worry is working too much, so that we are MORE tired when we return to the city. That has happened too often lately, a difficult balance, especially when we hurry because of snow and frost…

The house I just moved out of is over a hundred years old.

Yeah. Our crummy track homes made from 2x4s all last mich longer than 25 years. When I visited Germany, a friend of mine pointed out that all the houses there were made from concrete or similar. Some of those houses were much older. My first thought was, “How do they upgrade the wiring for things like Ethernet or even phones?”.

It seems wasteful to make a house out of sticks and then keep it up with caulk and tons of new drywall. But I guess it is not that clear cut.

Exactly, you simply can’t easily, if there isn’t something installed that you can replace.

There usually are strategical shafts and conduits for this, however depending on what changes the conduit or shaft either does not have the right properties, is too small, or whatever. It happens all the time.

Also Wifi is a nightmare, since each room is basically a Faraday cage.

LOL, that’s not how that works. ![]()

The framing is the primary structure.

On the outside you then have a cladding of usually DWD boards (vapour permeable wall and roof board) to which a decorative facade gets fixed.

On the inside, you usually have a vapour barrier (some kind of film) and than one or more layers of OSB board (oriented strand board).

The drywall plates are then usually mounted onto the OSB board, and are decorative and constitute a thermal mass, which is important to retain heat in cold climates.

The DWD and OSB boards on the inside and outside sandwich the primary structure, and thus form the secondary one. It’s basically a system of interconnected boxes, and if done right structurally super sound.

It’s much less wasteful than building everything out of concrete, relatively quick to build, can be pre-constructed in a factory and assembled locally, etc. .

That is not at all how my house was built.

Framing definitely is the structure. There is OSB on the outside and insulation between the framing. The inside is just drywall, tape, texture and paint. The outside isn’t wrapped with tyvek (my house us from 1979) and the outermost facade is engineered wood siding.

I have never seen OSB on the inside of any wall, commercial or residential here in the US. Here we use OSB for floors and the roof deck. Plywood goes on the outside sheathing, then tyvek vapor barrier, maybe foam insulation, then external cladding of some sort. Inside between the studs you get fiberglass insulation, or foam, plastic vapor barrier, then sheetrock.

It’s very similar though. I was writing about the ideal way structurally speaking, but doing only sheathing on the outside is sound, too. It has other downsides though.

OSB is better on the inside, since it’s slightly vapour permeable. DWD on the other hand is impermeable and you thus don’t need another vapour barrier on the outside. On the inside, you can either double up the OSB sheathing or install a slightly permeable vapour barrier between it and the main insulation. The vapour barrier on the inside is necessary to protect soft insulation from vapour and condensation from the inside. Spray insulation might be different, since it’s basically styrofoam, but we don’t do that here. Drywall is surely not enough, if you want good insulation.

We also put OSB be on the inside, because between it and the drywall, there’s often a small, also insulated space (ca. 6cm) for installations.

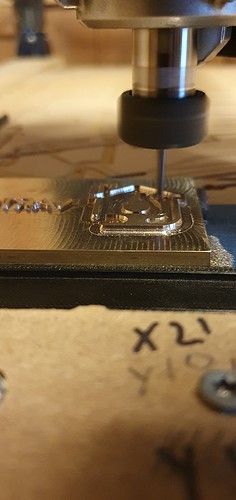

Cncjs to run a hot plate? You have gone too far!

Of all the hills to die on, you choose cncjs running a hotplate…