Here is something a builder should consider if you’re using stainless 0.065 tube: cutting the legs to an equal height.

This is how it came from Metal Supermarkets

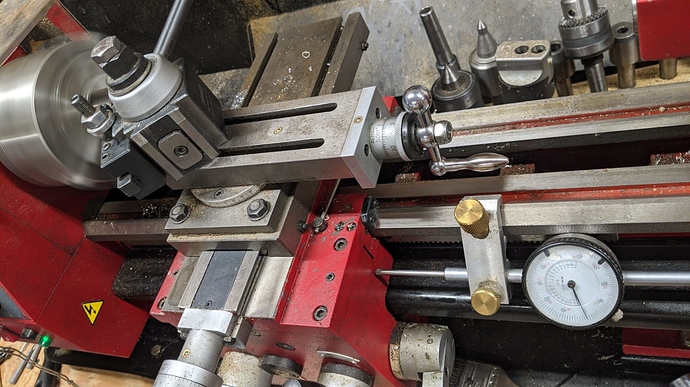

Be prepared to cut these precisely. I own a hacksaw, grinder with cutting wheel, and I was considering getting a portabandsaw as an excuse. But all of these options do not inspire confidence that I’ll have a 4 equal legs. Lucky for me a good friend offered to square the faces and cut them to size for me on his lathe. This is the most important thing to get right otherwise you’ll be shimming to get a level bed. Thanks again FP!