Hi everyone. First post here. I was hoping to complete my build and just show up here with a few pics of my completed machine and the cool things I made, but it’s looking like I could use some advice to get 'er finished.

So my progress thus far… since my shop space is limited I decided to get dual use out of my existing 4’ x 6’ workbench. Of course this bench was never particularly flat so the first part of the project was to plane it down with the router!

This worked pretty well and I ended up with a very flat surface.

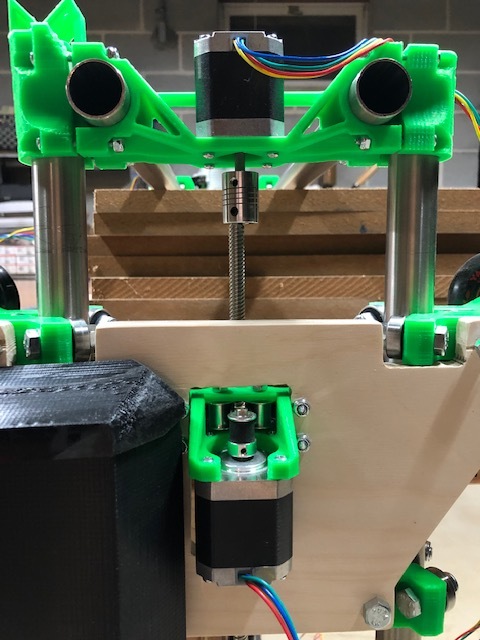

I had no real issues printing all the parts in bright green PLA on my cheapo Tevo Tarantula printer. I started with 1:1 templates and made the Y and 611 plates out of baltic birch using the bandsaw and drill press.

All of the subassemblies went together fine and this past Sunday I finally got the time to put everything together.

Everything seemed to be nice and square. The 611 plate moved freely along the X. The gantry moved up and down and the whole thing moved along the Y smoothly.

The problem I ran into is the alignment of the left Z axis lead screw. The right side lined up perfectly and moves without binding. Here is a pic of the misalignment on the left side

At this point I’m just not sure what I can adjust to bring it into alignment. The screws holding the T nut are already slightly loose.

Anyway, I’m very excited to get it completed and would appreciate any suggestions you might have.

thanks, Jeff