It was a lot of fun to just mess around.

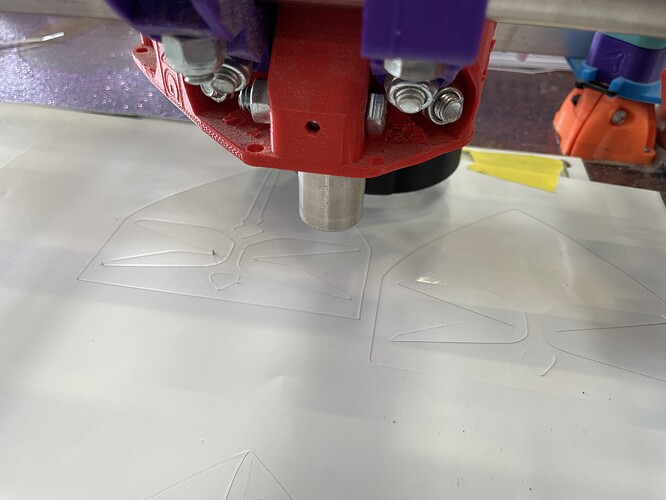

I used a single flute upcut 3mm.

I started at 20mms then tried 22.5mms and it didn’t seem to help much. For the first bit it was throwing nice swarf for sure. Then it was molten balls of plastic.

I was going to use two pieces of acrylic stacked together for the lr3 xy and xz plates for the lr3 but it’s quite flexible so I think I will stop at the lumber yard and get some mdf.

Everyone, chant with me: When in doubt trochoidal, when in doubt trochoidal, when in doubt trochoidal… ![]()

I have to do acryllic where I have to do some holes, I am nervous about that… ![]()

Troichoidal

Troichoidal

Haha haven’t even attempted that.

So a mid job ice cube dip is bad lol man I think of the silliest things sometimes.

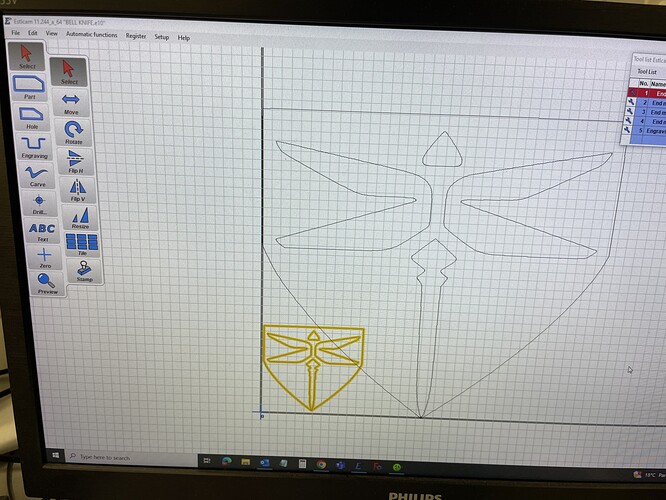

And yeah I tried using the “drill” in estlecam and it didn’t like it with the end mill much.

The first little cut I did worked very well

The larger one not so much.

I actually have drill bits that I bought because holes start smoking otherwise. ![]()

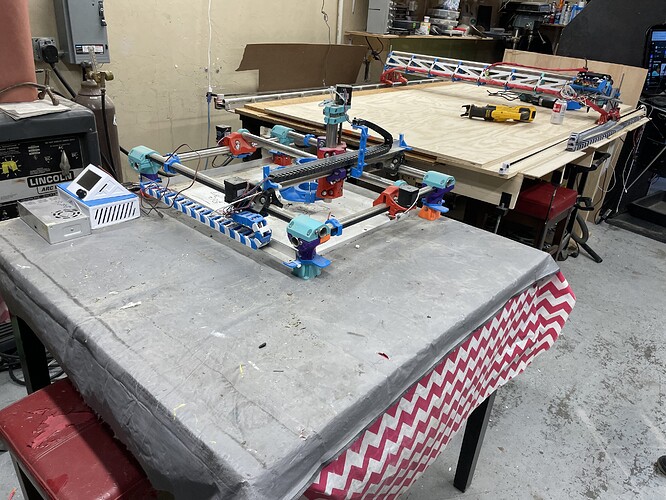

Been a while and it has been neglected since I have the lr3 going.

But now it’s time for it to evolve into the porta version haha.

Bringing it to work for masking and cutouts. Hopefully some engraving fun as well.

I know have one mpcnc and 4 decent clubs.

Bring my robot to work day! I really like that shot. Pretty cool to think you can bring that to work, get it working on some detail work while you get other things done. I love seeing that!

Yes it’s pretty versatile for sure !!!

I can’t wait to start testing it out on some vinyl and we have this wear pad material that we cut by hand right now but it would be nice to be able to use the machine for repeatable shapes.

Very excited to have it at work now I have a lot more room by the lr3.

I will drill some holes in it and put some hooks on my wall in the shop so I can hang it if I have to bring it home for a bit.

I love seeing portable CNC machines.

Hopefully you share more of how you’re using it.

Well in reality I only really used it to cut my lr3 parts and some minor things.

I will make sure to post up some of the neat things I do with it for sure.