Johnsons paste wax doesn’t have silica in it. Woodworkers use it on jigs and table saws and the silica stuff will make areas on the wood that won’t take finish.

Sadly not a product available in the UK. I’ll see if I can find a local aternative

Thx

Rob

Carnauba wax is what the main ingredient is just no silicone for sure silicone is used to help shed water to stop spotting after rain and also stops finish from spreading even

I’m sorry, I got confused by your answer.

You should you HAVE wax based on carnauba or NOT? If that is the stuff you want, there is tons on the amazon.co.uk.

I ordered https://www.amazon.co.uk/gp/product/B00YNHK3OE/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1 as it had Carnauba Wax in. If it’s wrong, it’s no big deal and I’ll use it for the motorbikes and car.

Yes the carnauba is good. Silicone is the bad one it repels the finish. Sorry about the confusion

Just turned up from Amazon, I’ll lightly run some wire wool over the steel tubes and then coat with the wax.

Rob

Looks like it will be perfect and give a long lasting shine and protection

If only that was me …

Rob

Being pulled in loads of directions of late so not done anything else, oh ordered some more end stops as got it in my head I need 8 as running dual end stops.

Am in work for a week then off for a week plan is to get it up and running that week.

Father in law is getting a table top sorted this week and is off same week as me, to get this up and running. Think only thing I’m missing is the cable now, but trying to hold off from buying until we look at roughly how much we will need.

Oh I need to look for a wiring help/guide for the skr pro and the mpcnc, anyone have one?

Matt

Why do you think you need eight stops? You only have them for the minimum on x and y. I asked about this some months ago and it was made clear that you only need four.

Holding off on wire is a good idea. I recall I used a lot more than I thought as I ended up going through the tubes themselves to keep things clean.

I also got rid of the drag chains on the board and used the spring steel inside a tape measure which then went inside nylon braid. The wires go inside as well and I mounted these on some light extra brackets on th x and y motors. This made a massive difference to keeping the bed clean and removed a trap for cuttings to hide in. Whilst drag chains look nice, they are difficult to clean.

We will talk eventually but currently up in Coniston.

All the best

Rob

Hi Rob,

I think me and father in law had got our heads mixed up so we’re thinking a stop on either end of X and y thus 8 in total.

Be good to see where you are with things we are aiming to get ours setup next week - I’ve got the week off so has father in law.

Matt

Matt

Am now back from Lake District. Free this evening (I need to clean the MPCNC as I left it with cuttings all over it). Back at work on Monday (sadly).

Rob

Hi Rob,

Sorry not seen your message.

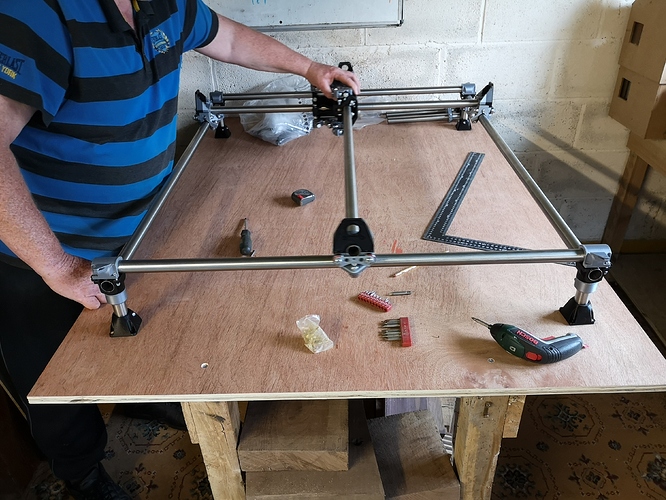

Just started putting it all together on a board in the workshop, see pic above.

Next step is tighten down I suppose, add belts and motors, then look at the wiring needed - this week off hasn’t gone as planned so only managed a few hours building today.

Matt

I wouldn’t tighten too much down now, loose fittings are fine, but I ended up taking things apart to connect cables and the like. I’d also be really, really careful on the feet and getting those screwed down right as they have (IMHO) a major impact on the rest of the MPCNC. If they are significantly out then, I don’t think you can adjust the rest so well.

I’d measure very carefully X and Y as well as the diagonals across the feet.

The other thing I’d check is that the height of the tubes that connect to the feet are identical. Sometimes the tubes can be perfect, but they don’t always connect all the way through and might be 1-2mm higher as the printer might have made the hole tight so the tube doesn’t quite go all the way.

This means you end up fighting everything to make it fit and you might have to go back to the beginning…

The tension on the toothed belts is important and very difficult to get right. I suspect most people tighten them too much as they think it’s vitally important. I did mine by moving plucking the belt and then putting a guitar tuner on it to listen to the note. However that didn’t work (would have been a great story if it did) so I just ended up plucking it and trying to feel the tension. Make sure the X axis and Y axis blocks are the same distance apart though otherwise they will feel different.

One other trick to check that the motors have current and do turn is to do a small movement using the console and then see if you can move the toothed pulley wheel with your fingers. Once the motor is energised it should be impossible for you to turn with your fingers. (Assuming you have fingers of normal size and don’t turn into a green giant when you lose your temper). Any movement at all means something is wrong. If you have the belts on, the belt will turn the motor so you can’t see that it’s not working until you try to calibrate it.

I also wouldn’t do the belts until I’d done the wiring so you can check that the motors turn the correct direction for each of them.

Ask me how I know how about these mistakes …

Rob

Rob,

Would this be ok for the wire?

Matt

Am thinking of getting that, may also practice rewiring the 3d printer while I’m messing around.

Also need to get an emergency off switch whole I think of things.

Matt

That should work. I prefer buying 4 wire ribbon cable though. It is annoying to keep loose wire like that together. Even if you use wire loom, you have to thread 4x as many cables through.

Hi Jeff,

Good point and thanks for the response, so would this be better:

Matt