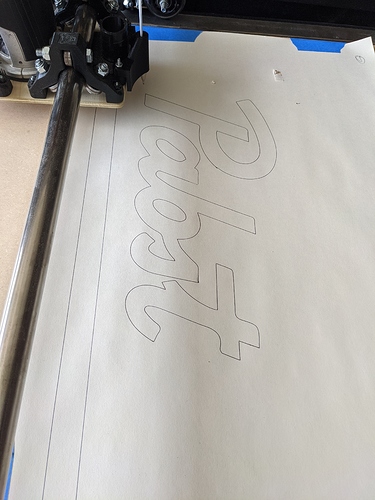

Tried 20mm/sec and went fine. Might try even faster.

30mm/sec worked, I think I am at the limit of how quick the z axis can move though

Well, your folks have a coffee farm…That is awesome! I bet all other coffee is nasty to you though. I just bought a bag to try it out, pretty excited.

@vicious1 definitely appreciate it when I have it. Thanks for ordering from them! I’ll make sure to let my dad know to put a little extra in with your order. Hope you enjoy it.

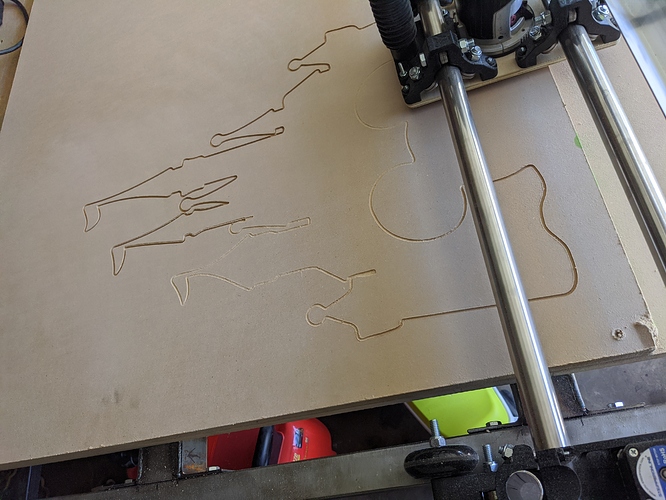

…well I found out my 1/8" bit is not long enough to cut through 3/4" material… Salvaging the piece by cutting it out by hand. My fault for not thinking to check that and won’t make that mistake again.

I’m curious - did it snap the bit when it tried to cut through? 1/8" shank or 1/4"?

@nijay No it didn’t snap, I was cutting with multiple passes at 2.5mm depth of cut with each pass. The issue was that the carriage got to a point where it was touching the material and was unable to cut any deeper. I failed to check that the bit was protruding at least 3/4" out from the bottom of the carriage.

Ah gotcha, thought it was a cutting length of the bit issue. Nevermind, carry on!

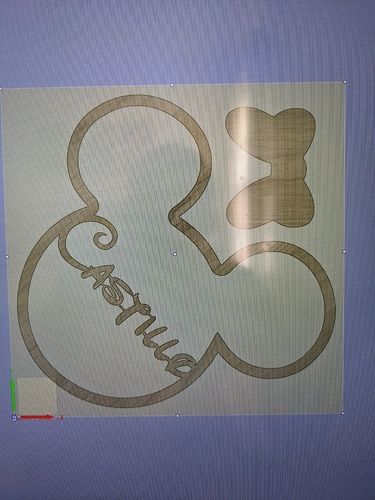

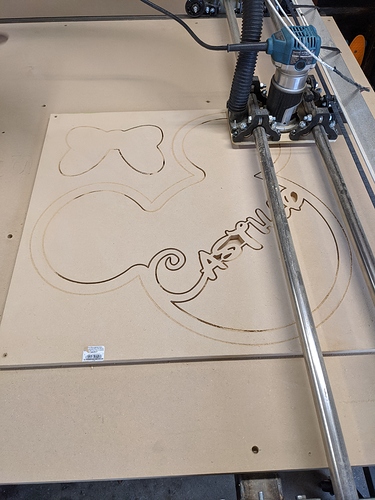

First commissioned cut on the table! Took just over an hour to cut. Modeled and processed in fusion 360, 10mm/s 3mm depth of cut. Sign is about 24" wide from ear to ear.

Got a package today…Tomorrow morning’s coffee is going to be very exciting. Thank you!

Did another Minnie mouse ear cutout for someone else. Got brave and tried 6.6 mm doc and 10mm/sec, definitely was pushing it, it came out fine but might back off on the speed a bit for the next thing. It did shave the toolpath time to 26 minutes from 1hr 5 minutes from the first one for same size.

Spent a few hours yesterday trying to recalibrate everything, but still seem to be out on the z over y distance (cutting close to 1mm deep into spoil board in one corner of the 2’ square project and not cutting through by about .2 mm on the opposite corner) as well as the front of my gantry seems to pick up before the back causing the router to be out of perpendicularity a little.

Not a big deal for cut outs but was hoping to dial this in for some engraving, though I did order a laser so that will be better for that anyway.

Also set up my tiny touch plate and that worked perfectly, way better than eyeballing it.

So either the table is off or it sounds like your far side might be a little tight or need grease. The other option is your rapids and plunges might be too fast, keep it under 8mm/s on the rapids for max power.

I’m thinking it’s probably a combination of all of that. I noticed that my gantry touches my spoil board because of the button head 6-32 screws I used, I’m going to replace those with flat head and counter sink them. That will probably allow me to get the xy mains to sit better which might fix the leaning gantry. From there if my gantry is perpendicular I’ll be able to surface my spoilboard which might solve the fading depth issue.

Looking closer at my table and looks like I need to put some work into it, seems that it’s got a bit of concave across the y length, probably causing the changing cut depth.