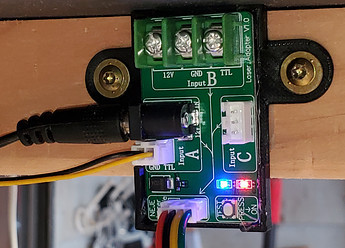

From the control board point of view you are all set. Looking at the laser control board:

The two wires coming out of the “A” connection go to your Rambo board. The yellow wire goes to pin 45, and the black to any ground.

There are some other things you will need to figure out. Your cutting will be greatly enhanced by using “air assist.” Most of the DIY rigs I see use an aquarium pump for air assist. As for the nozzle, @dkj4linux has kindly provided a 3D printed plate that replaces the red plate on the NEJE A40640 that includes a nozzle. I moved to his nozzle from my air assist solution, and I was very happy with the result. There are a couple of different versions. Read the last 3 dozen posts in this topic.

Consider also some metal to protect your spoil board, and something to lift your stock from the bed. Cutting is assisted by allowing some room for smoke and particles on the bottom side of your stock. There are commercial products for this task like this one. Search for the terms “aluminum honeycomb” and “laser bed.” But I see cheap DIY and household solutions as well. You don’t need much lift.

Also consider purchasing a decent and certified pair of laser glasses for the specific wavelength of this laser.