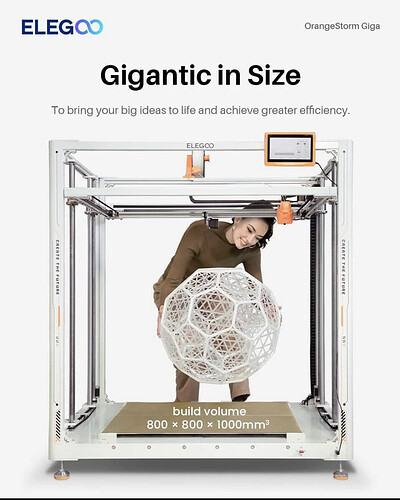

800x800x1000mm. That picture scale still doesn’t quite look right. I would look a lot more squished if I fit in 1m height. Maybe I am being too critical.

With no racism intended or implied: I had a friend/ client who was an Asian immigrant. He was setting up an office for eight people in a room of around 8m2- I told him it couldn’t possibly work.

He looked at me deadpan and in his very thick Cantonese accent said something I will never forget

-“ Is OK. We very small people.”

I suspect the girl in the pic is one of his ex employees!![]()

Yes it looks off. Maybe she is a couple feet back leaning in.

I bet there is a good career in being an undersized model. Need to be proportional just smaller so that the product appears larger than real life.

Ran into this today:

Not sure what field of engineering inspires this stuff but really neat. Looks like magic to me no idea how they would do the calculations for this to make it repeatable.

Maybe, but there are plenty of camera tricks available. (Reference: “Special Features” discs from the Lord of the Rings trilogy. Plenty of things they did to make people seem Hobbit sized.)

So I had a play to see what she’d really look like.

It’s guess work of course, but if you look at the build plate at 800mm and create a girl who at 1.6mm is still not tall by any means (and inch shorter than the average US female), she’d look a bit like this.

All that bumpy head stuff and a build plate 6" off the ground means this would be a pig of a thing to work with - so in reality you’d want the machine on a stand about 70cm high I’d reckon - with the build plate a little under normal bench height and you’d need a step to reach the 1kg spool of filament to refill it every ten minutes or so.

Lifting a twenty kilogram model from that plate might not look as glamourous though.

Why do marketing people think this is OK, and why do Manager’s believe what they say?

… Well, my sister is 154cm. In my kendo class there are 4 women under 160cm, all adults, going from 148cm to 159cm. (1 is Japanese, one Chinese, and one is half Japanese, but the other isn’t Asian at all.)

Well, unless that’s a real monster of a hotend, it may not go through 1kg of filament any faster, or at least not MUCH faster. Assume maybe a Volcano or equivalent, but the value of that build volume to me would be vase mode prints, or very open models (as pictured) rather than monolithic blocks. Maybe print an RC plane wing in one piece at very low infill.

Interesting - I’m thinking about a bloke that uses a lot of red filament to make tank parts and clocks and statues of himself. He was recently advocating that manufacturers stop talking about speed in terms of acceleration and mm per second, and just measure volume of plastic throughput.

I know a couple of companies who prototype car parts and another that makes museum props, who would agree with Ivan.

Hey I’m just quoting the statistics! ![]() (That’s what makes it an average I guess).

(That’s what makes it an average I guess).

Maybe it’s the “short-ish” person’s printer and it doesn’t need to be elevated. All I know is that at 190cm, I’m not the tallest rooster in the hen house and it would be a proper cow for me to work on in that position! Stick your printer on a couple of filament boxes on the floor and put a bar 1m above it and try that on for size.

You’d be as fit as the world Pilates Yoga Limbo champion in a day!

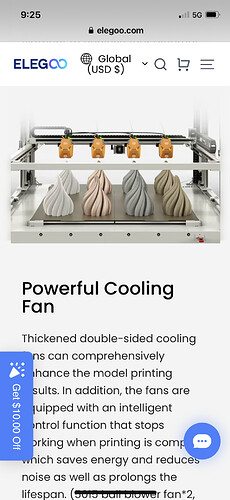

Multi head

ready for hot printing and 300mms

Also more pics of the mysterious lady.

Cheap too sounds like 1300.00 usd

At this point I ask the question - if I have a problem with one head, doesn’t that mean that I’ve just knocked out all of my production capability?

As a devil’s advocate - if the purpose is not for colour changes or whatever, how is that better than four machines in a commercial environment?

I guess if I was making plastic meringues commercially it would be appealing!

On the other hand, it’s nice to see different evolutionary paths here.

I have a reply to that, but I think even I would get banned for it. ![]()

I’m late to this reply (regarding measuring stuff for the wife).

I do carry a tape measure if we’re going to be walking around a furniture store. I use the camera on the phone to snap photos of the dimensions instead of writing them down on a pad, though. Plus, that means I usually get some pictures of extra angles for duplicating it later.

He did it without any gcode or stepper motors. It’s all done by switches and gearing.

I take it you haven’t seen the water soluble support filaments yet?

I have 2 elegoo printers and I have abused the crap out of them and they are great. Literally over all the years only the tension deal snapped.

I carry it to work pretty much every other day.

I have never really ever had much trouble printing at all even tpu

Or I wonder if you could use the LWPLA and bond in pla plus supports like spars for wings etc.

Omg! Classic!!

Oh no, I’m quite aware of water soluble supports and the reasons you’d use multi heads (or multi filament heads) but this to my mind is odd:

Three additional printheads can be added to the X-axis to realize simultaneous printing with four nozzles, supporting printing four of the same model,while each nozzle can be equipped with the same material and different color filament to achieve four different colored models of the same kind.

There’s no mention of them being used other than simultaneously. and of course with only a quarter of the print bed width (200mm) available to do that, where’s the benefit? I went looking for answers but didn’t find any, but I did have a few other questions answered.

It comes with a large spool hold

And a tiny one, with a much bigger version of the girl.

And for a presumably not oversized bloke, the control panel is just above elbow height, which is about right.

This is my biggest concern though - apart from the fact that I’d never get up again - could you realistically kneel on the floor and reach over 600mm to wrestle a print of an 800 build plate?

It’s a nicely styled clip, and I love their little fluffy white dog Diesel, and the concept of the printer as a home appliance. I’m not sure if picking little strands of filament out of the shag pile rug on a daily basis won’t send their beige little brains into a tail spin though.

All valid points

It’s running klipper I believe so pretty easy to customize tho.

The multi prints could be useful for some things like strut braces etc.

and I can see this thing using a lot of filament.

They are imo a decently reputable company I love their water wash resins.

Better than that tough blue stuff anyways. And what do you got against fluff balls lol

I just instantly thought interior panels for automotive, and some molds.

Realistically it’s out of my fun money budget anyways.

I did reach out to them years ago to see what they have in the works more metal sintering setups, but they have nothing in the go rn.