@RobP I created the “normal” inlay first, you can see it further up. If I now cut out where it is supposed to go it won’t fit.

I therefore ran the program a second time with 5mm as a starting depth (if I had just run it a second time by just setting 0 5mm lower, it would have destroyed the first cut since Z travel height is only 3mm). It then takes of 5mm more, so it will fit a dephts of 5mm. Sometimes it cuts through 10mm of material, but never with the whole endmill, so that was okay.

This is the cut in the board, 5mm deep, so for the inlay to fit it has to be double the depth.

One thing I did not consider was the tip of the 60° endmill: it left some material standing in the one on the left below (there was also some in the big circles, I ran the program for those a second time with automatic depth limiting). I marked some (former) problems with red circles.

I manually removed some of those with a chisel, but it would have just been better to leave the depth of the engraving bit to auto anyway, because none of the cuts is wider than 10mm, so it cuts the pockets deeper and would get rid of my problems. I don’t think it would make the glueup more unstable.

I hope this was more clear now.

Aha, so youre doing a full 3D carve, not “faking” it with a 2D tool path and offsets. That makes a lot more sense and now I see why the process is relatively simple.

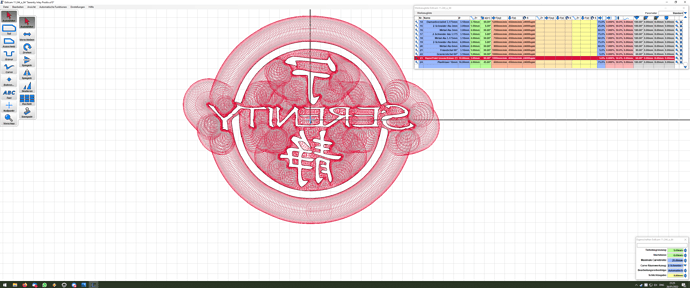

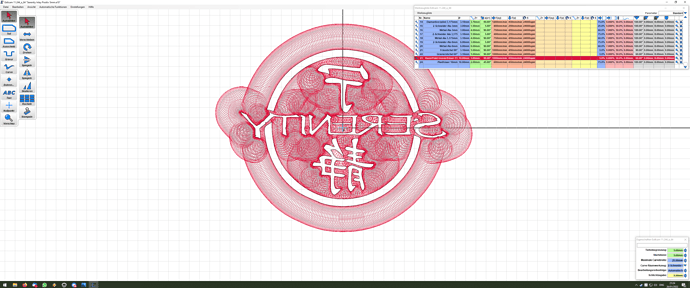

Nah, it is actually 2D, with a V-Bit (Sorotec Online-Shop - VHM-Gravierfräser). It’s just the one highlighted in the pictures (and a 6mm to clear some stuff).

What I mean is you are doing a “carve” operation and not “part” or “hole” (or pocket or island). That tool path moves in 3 dimensions and cuts with variable depth.

The complicated (what I call 2D) approach uses a constant depth with “part” or “hole” operations and then you have to do all sorts of calculations and offsets to trick Estlcam into producing the correct output, and sharp corners are not even possible.

Oh, I understand now: it’s a carve.

It did not work out as well as I expected. It seems shallow, wide Inlays are more easy. For the very filigrane letters it wasn’t deep enough with the 60° endmill. I now ordered a 30° and will be trying it again. The cuts should be a lot deeper then.

I put glue and oak dust into the cracks, hoping it will look at least decent. It was only my second inlay, I flew to close to the engine of a firefly and got burned.

There are a lot of things I worry about, and I’m not sure of the relative importance.

- Squareness of the machine (can be mitigated with 45 degree flip)

- Flatness of top surface (can be mitigated with surfacing prior to carve)

- Tool runout (behaves like bit with slightly blunt tip)

- No finishing pass

One thing that might help is (if the design allows), to split the plugs into multiple pieces. (Carve them all at once but chop it up before gluing.) That way each piece can float separately from the others and find its own best location and depth, rather than a single global offset, rotation, and depth that tries to satisfy all pieces.

Maybe something similar to a finishing pass could be achieved by carving each piece twice with a slightly deeper Z the second time.

Impressive work you’re dealing with! Just a thought- would the contrast of the inlay be more striking if you used wood that went along the grain, instead of across the end grain? Working on the endgrain is also more difficult for the mill, rather than from the side.

Since it’s going to be a cutting board it needs the end grain (though I am not sure that I understand your question correctly). It would have looked better with different, darker wood and without the chessboard I guess.

After a few weeks of searching I now found a woodworker who sells small amounts of lumber to non-business, otherwise it is nearly impossible to get non-glued wood except fir. -_-

I actually also thought about the squareness that it might be the problem. I am going to try that out. It could also have been a bit of runout because it had to mill 10mm in some places (not the whole tool width, but still).

Cutting the one thing into several pieces would be pretty impossible, but separating the writing from the symbols etc. should be doable in separate carves.

I downloaded F-engrave today and found a pretty good tutorial for it, gonna try this the next time so I don’t need my workaround. The guy in the video made it sound good (but his result wasn’t that great either… :D)

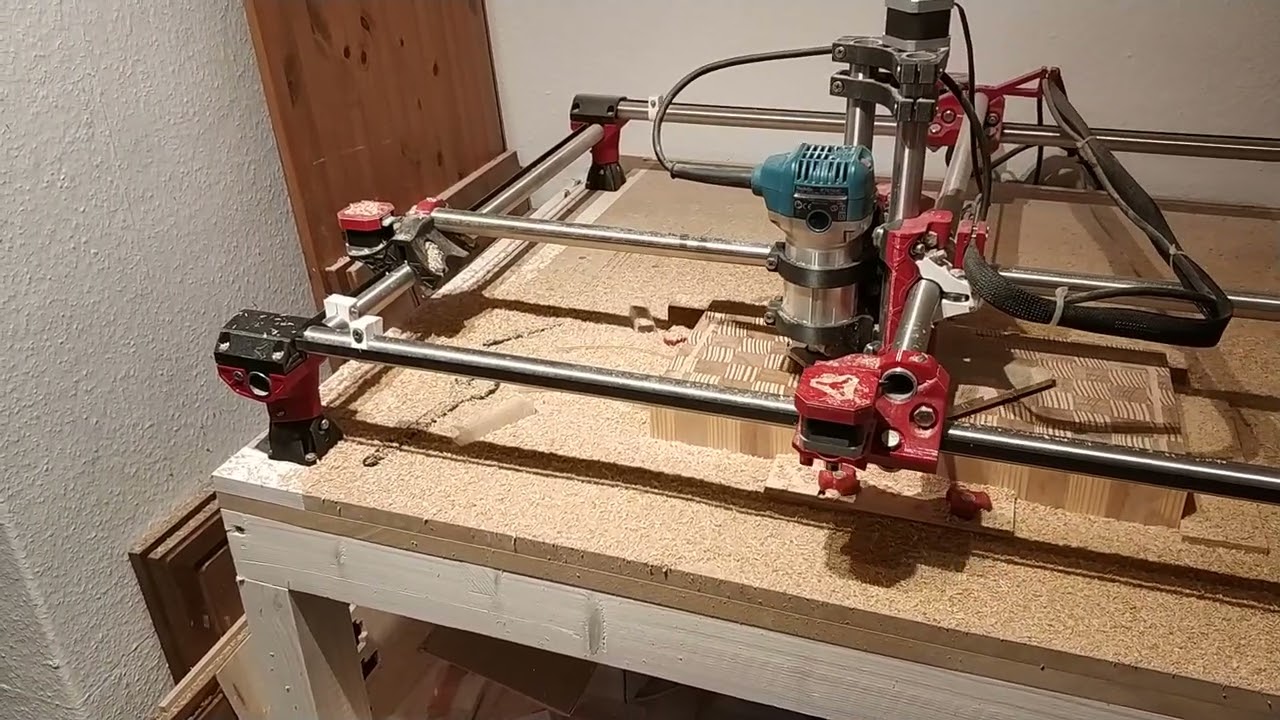

I also made a video for you planing end-grain oak at 2000mm/min and 5mm DOC with my 16mm endmill and a relatively low speed of 3 on the Makita, whatever RPM that might be… The chips are flying and the MPCNC did not even stutter once.

Impressive! And live-action or video, I doubt it ever gets old watching a CNC machine at work.

Ohhhhhh, I have a ton of pallets at work for those cleats!!!

Got me some wood. Ash and Maple. The Ash looks so stunning when planed.

Maple:

Ash:

A lot of it… Two boards:

Planing the maple:

Clamped together. Look how beautiful that Ash is. I am blown away by it:

It’s going to be a cutting board for my brother’s birthday. Hopefully on time.

I now mixed F-Engrave and Estlcam, because I could by the life of me not figure out how to separately cut the keys them with F-Engrave and set the 0 freely. So I made the cutout with Estlcam (2 Layers) and cut the keys with F-Engrave. That works pretty well. There are some really, really minor gaps, but I am happy. Will cut the other key in the next days. Hopefully it also fits.

I upgraded Schneewittchen and gave her a drag chain for the Z-Axis. The tape measure trick didn’t work out since it would always get caught on the stepper on the right side. Ugh. Now it is working like a charm, though I couldn’t spend much time with her because of my new baby girl (like, a real girl, not a lowrider or sth… :D).

First “real” video with a simple project my wife wanted me to do. First time with the camera, no boom arm yet. ![]()

Watching it I am thinking I could have shortened it a bit more. ![]()

Hi Philipp,

deine MPCNC ist echt nice und deine Printed Parts sehen Hammer aus. Hattest du beim Zusammenbau irgendwelche Probleme, das etwas nicht passte? Meine Z-Achse macht mir große Schwierigkeiten. Die Kugellager haben nicht gleichzeitig Kontakt und dadruch ist alles etwas wacklig.

Vielleicht hast du ja einen Tipp…ich werkel schon seit etwa 6 Monaten an der MPCNC rum und bekomme einfach kein dreh rein.

Liebe Grüße aus Bremen