I’m still reading through, so I don’t know if anyone has brought it up, but I use Pirateship.com and it saves me a lot compared to paypal pricing.

Shopify pricing and pirateship are the same. I do use both though just to keep an eye on it.

Still chipping away at the lists.

This morning I put up the new shop, and some minor docs updates. Still working on sourcing, pricing, the store options, videos, and features. SLOW progress is still progress.

Here’s a link to a regular event at Noisebridge called “5 minutes of fame” where you can present something and it gets out to a lot of people:

It’s kind of fun and there were a lot of attendees and viewers last time I attended.

I’ll keep an eye out for the next one, and browse through the Youtube channel.

I spent a bit of time at the link Mike (@dart1280) provided to the Competitor’s website. A lot of the follow-up forum comments to Mikie’s post related to the framework of that site, but some of the content jumped out to me…content that, if it exists on the V1 website, I’ve not aware of it.

First is their planning page. This is a nice graphical roadmap of the process of building their machine. Most of the nodes of the graph are links that take the user to additional information for that node. Obviously, the roadmap for an MPCNC would be different, and there are likely other ways of presenting a roadmap, but I could see a lot of the information that we repeatedly provide on the forum slotted nicely into a visual graph of some sort. The way I see it, a roadmap focuses on information that helps make decisions, not on information for doing the actual build.

And second, is a gallery of builds. We have galleries of things people make, but I am unaware of a gallery of all the machines. I don’t know if this kind of gallery has value. I thought it might provide some confidence to uncertain builders, and perhaps a visual source of ideas. I know that when I was building my Burly, I was doing Google image searches of MPCNC machines to see how certain problems were solved. I thought it might work like the Things-You’ve-Made galleries where, when someone post a picture of their completed build, it can be tagged and then automatically built into a gallery with link to the topic.

That is a great idea. Our road map could be significantly less involved as well. I am adding it to the list.

We do have a build gallery but we have not stayed on top of it. Good news, it is easy to go back and add to. I will need to add these a bit more prominently. (suggestions appreciated, as well as where to link starter projects and user features.)

SO I have still been chipping away at the list, I actually just got the email this morning that some of the site fixes are ready for review. When those get checked out I will work on transitioning the main site to shopify (worried about linked docs picture though).

An easy to discover gallery of the machines (by type and size), their tables and dust/noise enclosures, together with summary of notable mods/differences would be helpful.

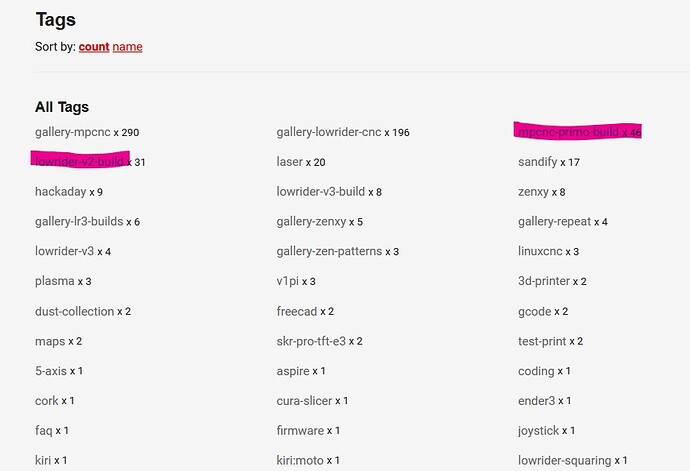

Some tags along these lines exist, but looks like some consistency (wrt naming convention), consolidation and fixing-up is needed. Have been guessing what tags to use, some authoritative guidance would be appreciated.

https://forum.v1e.com/tag/mpcnc-primo-build

https://forum.v1e.com/tag/gallery-lr3-builds

https://forum.v1e.com/tag/lowrider-v3-build

https://forum.v1e.com/tag/lowrider-v2-build

Currently, have been making unshared notes on challenges/ideas as I stumble onto stuff, guessing others are doing this too. Ideally, would prefer to be contributing to a shared space, reducing duplicated silo’d efforts.

P.S. I know it seems like this list is taking way to long, but in all honesty, each item I have on the list adds a few more pre steps to make it happen. Nothing on there is as easy as “add a picture here”, I usually have to build something to take that picture, then edits to add the picture. I think I have knocked out the easy stuff, and the list is currently getting linger not shorter.

And today I am so freaking sick I am not sure what I can get done today.

I can run through these and consolidate them. I have been working on those tags since we started the list and I have been focused on getting rid of the one’s and two’s.

I know it seems like this list is taking way to long

Actually, I’m surprised you have made as much progress as you have. It seems like this forum topic has stacked up a decade of work for one person, and I tense up a bit every time I see new potential work appear on this topic. Of course, that did not stop me from posting.

I still appreciate it. It is kind of molding the site. New groups of links are forming, I think… Still have a lot of work to do though and I think it is worth it.

The New to CNC idea could easily link all of today’s ideas and for a solid page and knock out a chunk of the list.

I’ve been lurking here for a while, reading up on the MPCNC, and I already ordered some of the components needed to build one.

From a quality engineer perspective maybe I can offer some insight into the mind of a customer, do an “audit” on the various steps building the machine (planning, purchasing, building, first steps) and rate each experience.

My first few random notes:

-

I imagine many of the people looking into MPCNC already have a 3D printer and are looking for projects they can do with it. What does this mean? This means they have some assembly/troubleshooting experience with a CNC machine. That is who I would focus on.

-

What I could see as an improvement in the “image” of an MPCNC is have a standard recommended model that you can expand if needed. Let’s say the building guide would say “here’s the standard MPCNC, it has a 600x400x81mm work area, uses stainless steel tubing, an SKR controller and a makita RT0700, you can expect to mill hardwood with an accuracy of 0.3mm, aluminium is possible but slow” and then show some examples (videos, photos)

-

The mechanical assembly guide seems pretty straight forward

-

By far the most complicated topic for me and I’m still undecided on this one is the electronics/wiring. I’m still not sure I need endstops, what board options I have, which one is better and why. The standard model could solve this with standard wire lengths, a standard board+firmware, endstops as standard.

-

Safety - a kill switch should be standard and included in the guides, some basic safety tips (remember many people are coming from 3D printers where you don’t have flying debris coming from the hotend), enclosure options and ideas would be welcome.

-

I also support the idea of a more comprehensive set of instructions such as a PDF file, or something similar to what Prusa did, adding a comment section to every step of the build guide. Funny thing is, took me a good few days to realize that there is a submenu in the guide (Home-Build-Control-Use-Learn), but it doesn’t show up if my browser is smaller than about 60% of my computer screen.

Thank you, that is quality insight.

This does change over time. The first couple years this was mainly a large format printer. Most people didn’t care about milling at all. So important to keep this fluid.

For this point, I would love to define some things…without promising anything. I could use loose language like, “up to x.xxmm” or “MRR up to XX”. This is a touchy example but what happens when someone like Tom S Can’t get it to mill wood? Clearly the machine can easily do it, but for some unknown reason it was the worst build performance we had ever seen. So I guess what is the proper way to put bounds on things. “Theoretical resolution of 0.0003125mm/XY and 0.000078125mmZ with an expected real world resolution of 0.05mm?” (PS those are real theoretical numbers at 32nd stepping, the TMC’s use up to 128)

One I do not think has been mentioned yet. I have never even told anyone to be sure to wear eye protection (we talk about hearing protection, though). Can’t believe we all overlooked this, I think that shows the level of maker we assumed we were dealing with. I am making a not to include some basic safety tips in the docs.

It should be a menu when you scroll down, but if you did not see it I need to change that back. It is a change I just made last week. Back to how it was.

Holy crap! I know I’ve mentioned it, and it was pne if the first things I purchased for using the machine, even before I bought my Makita router. I have eye protection for the table saw already, but bought another set for the basement where the CNC is. It only just clicked that it isn’t in the instructions…

I’m guessing the instructions for the router suggest ear and eye protection. And don’t use the router in the bath tub, etc.

And don’t lick it when it’s running!

The thread is pretty long now and I didn’t have the time to read through all of it, but it would be nice to have some collection of DXFs etc. I always post them in my build threads, but they might not be found there.

Strongly urge users to verify that it is cool enough to lick before licking… And when milling metals, remove any metal shards before applying tongue (unless that’s really what they’re into, but that’s a whole 'nother forum).

A tag can be added, then we could easily keep a list of them. DXF’s are not the end all be all though, so the actual source would probably be a better option, especially if there is any fitting or joinery.

DXF, stl, CAD, and any vector file could all be grouped as a project file. Not clear the best way to do it. though. I do plan on adding a few small projects, anything I don’t add I do want to keep it clear who can answer questions about them.

So is that a new forum section, or just a “project” tag?