Robert,

Effective air-assist does indeed do all those things – it suppresses flames, helps with clearing debris from the kerf, and keeps smoke/soot from attenuating the beam while also protecting the lens. It clearly helps during most cutting operations but is often not needed/desired during engraving operations. But the key IMO is that it needs to be both effective and controllable… strong when cutting, minimal when engraving, and directed properly into the kerf regardless of the direction of travel. So, I modeled this air-assist setup similar to any number of CO2 lasers machines on the market… thinking that they would know best how to do this stuff

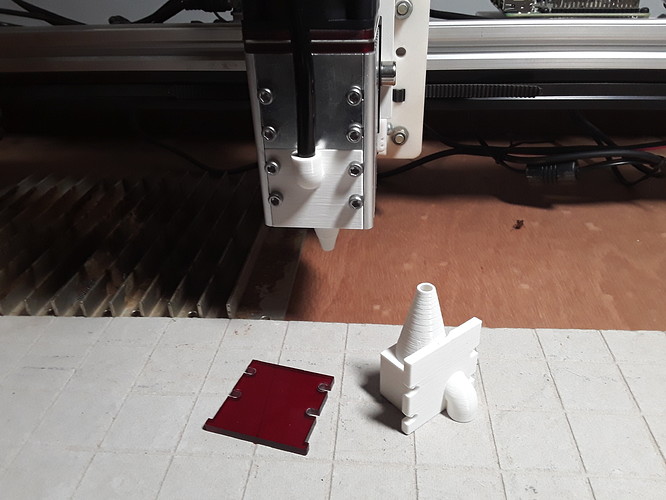

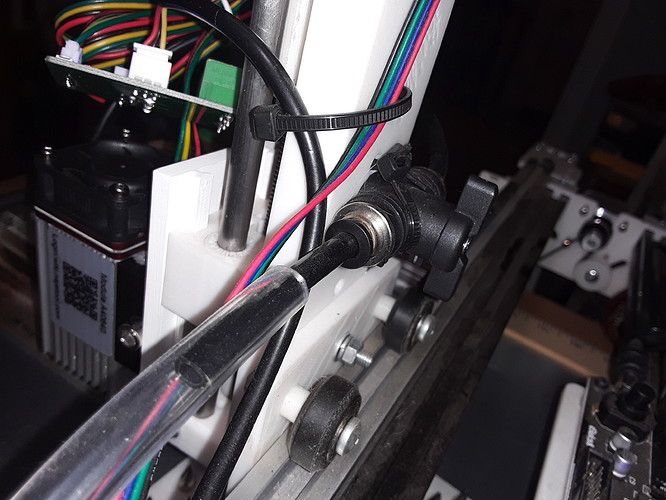

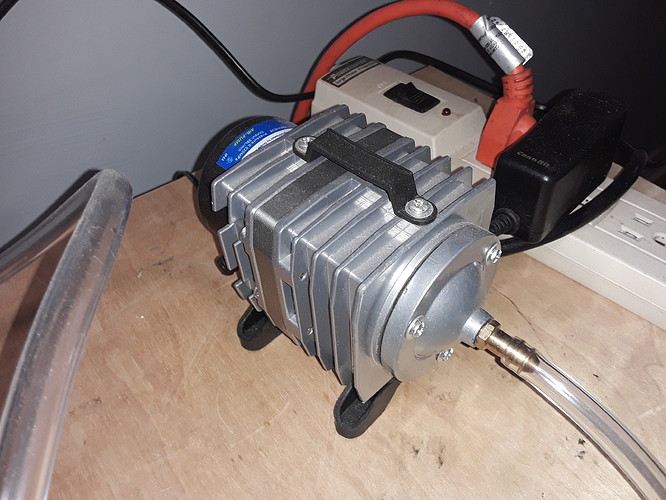

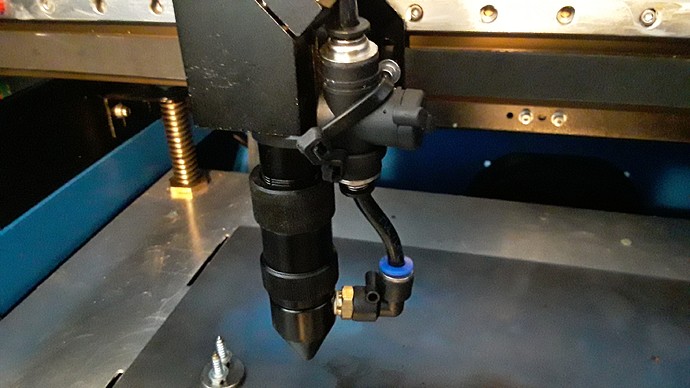

My setup consists of a nozzle, a ball-valve (zip-tied to back of X-carriage), and a modest compressor…

Obviously, I’m set up to manually control the air-assist with the ball-valve but you can always segment your laser job into separate cutting and engraving files… or take your chances adjusting it “on the fly” (Grbl allows easy job pause and resume…). Also, depending on the material and its thickness, I run “wide-open” air-assist when cutting thicker material and “just barely” air-assist to engrave… barely enough to keep positive pressure in the nozzle so smoke can’t enter and coat the lens.

I don’t remember if this video is one that deals with air-assist but ol’ Russ at SarbarMultimedia has many [very!] in-depth videos that deal with all things laser… use the “search” function to find videos that have anything to do with air-assist.

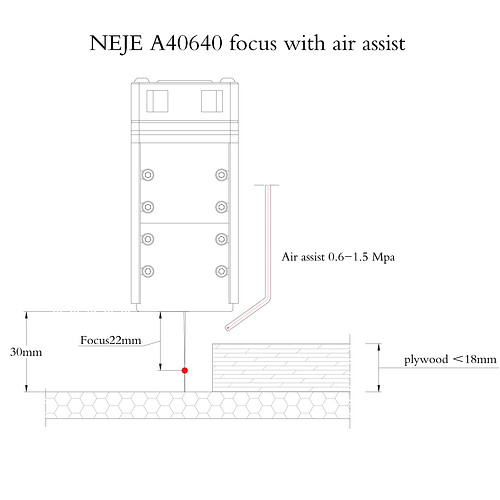

When I first tested my A40460 laser I measured about ~22mm from the bottom of the housing to the focus point, similar to this drawing from the Neje website…

Yours isn’t about 22mm as shown? After confirming mine was set about “right”, I used that to set the dimensions of my nozzle.

I’m sorry you’ve not done tiles yet. I found those to be one of the most satisfying “products” I’ve ever produced with a laser…

Interestingly, these were done with a lowly Banggood/Eleksmaker 2.5W diode laser… and no air-assist was required. I hope you’ll try again. It’s not a difficult process at all and the results can be stunning. I’ll gladly help as I can…

– David