Very neat project I didn’t even know why this magic was lmao.

I had a couple of ideas for tip longevity and for keeping temps down if your accepting input ?

Just the tip, you say? ![]()

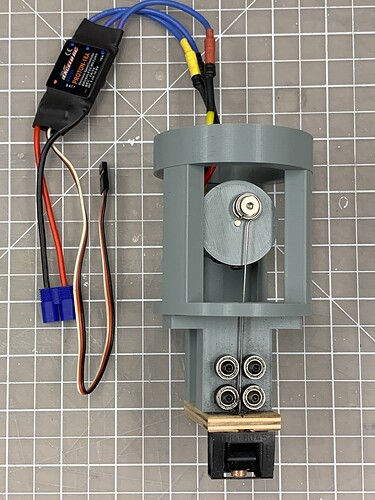

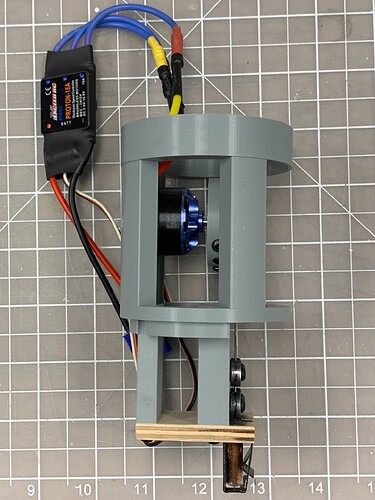

FWIW - I haven’t melted anything on my needle cutter yet. It can get a little warm in operation but works really well. Like a lot of us, I scrounged up parts from what I had on hand. DC brushless motor, 18A brushless ESC, servo tester for speed control, separate 12v power supply, mig welder tip and an aluminum heat sink that is intended to be used with a power transistor. I designed the frame to drop into the Dewalt 611 housing on my LR2.

Very nice-looking needle-cutter, Paul. I’m thrilled it’s been working well for you.

![]()

– David

Haha that was going to be my tip idea lol

I even made a quick example, but I wanted to add some self abrading dry lubricant. (Basically high temp paint with graphite flakes)

And the mig tips are perfect for 1/4” tube to tap with a m6x1 tap and then thread in.

Pot the graphite inside the tube to cut friction down. But it would make a grey line. So then I thought solder a larger tube onto the outside of this one then have a ice cube tray at the top with a little hoper.

Well… I have MIG welder tips… but they are ontended to be used on the MIG welder… I also have this 1/16" copper tube. I forget the exact wall thickness, but it’s less than 1mm inside diameter, actually not too much larger than the needle wire, so… I’m using it.

When that tube is soldered to the brass, it seems to work well.

As a part of my regular kendo maintenance stuff, I always have a lot of light mineral oil on hand and eye droppers. That should keep everything lubricated without making too much mess.

I finally got batteries for the tachometer, but I took the driven axle out. I ran the cutter for 1/2 hour just to see, and took the gears out tk see how the needle had worn the nylon… I can’t see any excess wear, so I’ll call that OK for now. I still figure that I can put in a copper bushing. But I did find a problem. The axle wants to walk out of the bearings. I originally.planned to groove the axle fkr an E clip, but then decided not to as it seemed tight enough, but looks like I am going to go back to that idea.

Are these files shared anywhere? That might be perfect for me (if I ever get some free time).

The public files are in OnShape. Search for 611 Needle Cutter. Sorry, I don’t recall the exact motor I used but, it was a 2822 (exterior dimensions) 1200kv brushless outrunner.