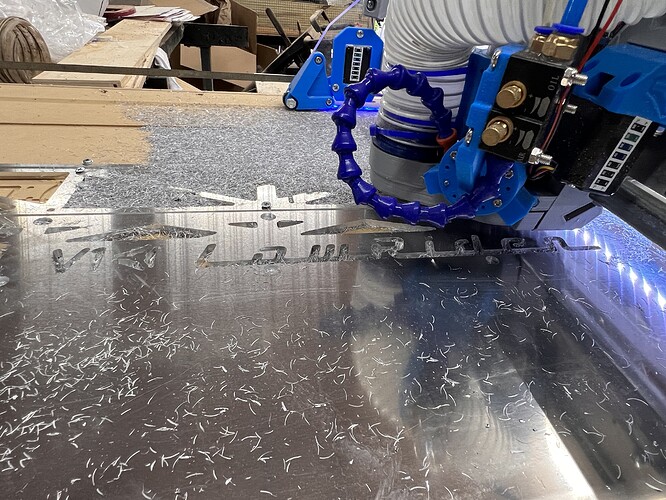

LowRiders have been used successfully for cutting not only aluminum but even steel. Here is a pic and link to a thread in which a LowRider is being used to cut quarter inch thick aluminum at full depth of cut (with trachoidal milling).

In making my LowRider, I followed the example of Dan, @SupraGuy, in making my YZ plate taller than normal. I have yet to actually use that extra height other than just getting better access underneath the unit for bit changes and cleaning. However, I’m confident that if I wanted to do some 3-D shaping and cutting, the LowRider would perform well within that added height.

I am a huge fan of the LowRider. In my estimation, it is the perfect balance of capability, strength, rigidity, and affordability.