Think I still do not understand the problem to the full extend.

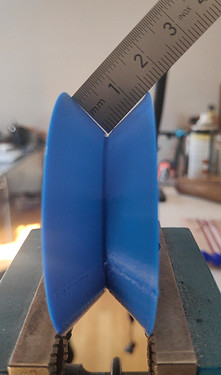

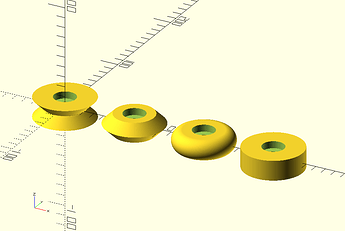

I just designed and printed a wheel with a inward groove 60mm heigh and 20mm wide in TPU.

The model can be downloaded from the prusa website here.

When I measure one side of the groove I get a bit less than 15 mm which would be ideal for a 15x15x2 mm L profile.

I still can not see where the L-profile will clash with the wheel brackets.

Please can you explain to me what my mistake in thinking is?

Here are some photos: