It would be awesome if you could pair it with air assist for cleaner etching, deeper cuts, and to save your lens/extend the life span of the laser, like Ryan recommends at Main - V1 Engineering Documentation

I already have one that I’ve not ever used yet. This could be a good initiation for it.

So far as I can see, the E40 just has a metal provision for air assist. It also seems to be a bit longer focal length, which is probably the biggest advantage. I’ve melted a few plastic air assist pieces now because of inadequate air flow when a hose gets pinched. I have some ideas for the A40640 that I want to try.

Cool, thanks for the explanation!

Are you sure? From my research, the E40 has a much shorter focal length resulting in a very minimal distance between the module and the stock. You can adjust the focus on the A409640 for a short focal distance, but most of them come with the lens screwed in which gives about 20mm of distance between the cowling and the stock. The air assist solution may take part of this distance depending on the solution.

The E40 is a fixed focus, they say 5mm from the heat sink. The A40640 is variable focus, they say 30-70mm from the lens but 30mm seems to still be inside the heat sink, and I’ve never managed to get an acceptable focus where there is more than a couple of mm from the heat sink. The E40 laser looks like it is higher up in the mechanism as well, as the heat sink is taller. This implies a tighter cone from the focus more suitable to cutting. Also at longer focal lengths, the A40640 starts to distort the beam pattern and you don’t get as tight a spot. (NEJE recommends focusing 2-3mm from the heat sink.)

Am I sure? Well, no. These are my impressions from the 2 modules side-by-side.

I’ve always used my A40640 with the lens screwed all the way down (longest focal distance). With the lens in this position, I’ve tried a number of focus tests in order to figure out the distance. For engraving, my spacer (used from the heat sink) is 19.8mm. For cutting, my spacer is 18.2mm (places the focus point in the material). My kerf adjustment for boxes is 0.09mm, so the kerf is about twice that number at 0.18mm. My resolution for engraving is about 300lpi. I get banding if I go in tighter.

From the videos I’ve watched (like this one) , it looks like the E40 is much closer than 20mm. Visually it looks like the focus distance from the heat sink is about 5mm, and the presenter of the above video complains about the close focus distance not leaving any room for hold downs.

Seems like I may need to play with the focus on mine more.

Like I said, NEJE recommends setting the focus 2-3mm from the heat sink, and that’s where mine is currently. I see the laser spot getting larger at the further distance with it (I thought) appropriately focused, and notably less square.

Honestly I use my 5.5W Genmitsu laser a lot more than the NEJE modules, because it’s permanently emplaced in a machine, and I don’t have to change anything out. The A40640 will probably get its own machine, and the E40 will take the LR3 spot.

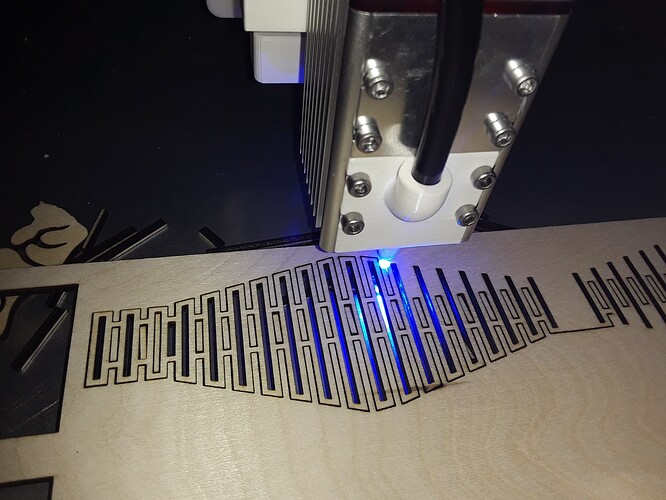

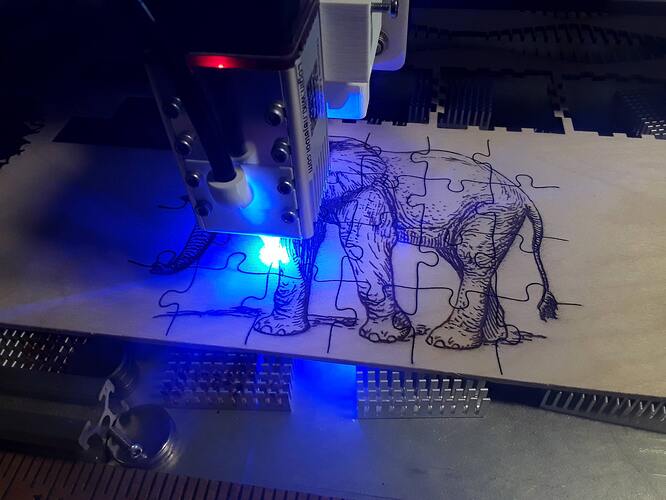

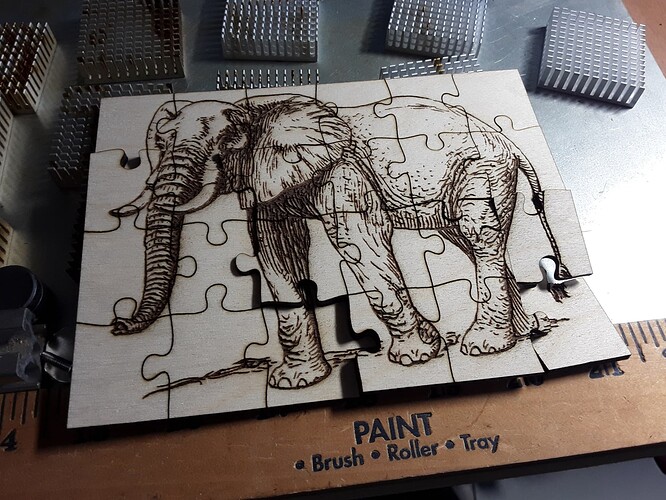

I purchased three Neje A40640’s (pre-E40)… and designed an air-assist nozzle that extends 15mm below the bottom edge of the housing. All three of my Neje A40640, as delivered and never adjusted, focused 20mm - 22mm from the bottom edge… leaving 5mm - 7mm from the nozzle tip to material surface. Here, I’m engraving and cutting 3mm plywood in one pass…

– David