Does anyone know if there is a Klipper printer.cfg profile out there for the LR2?

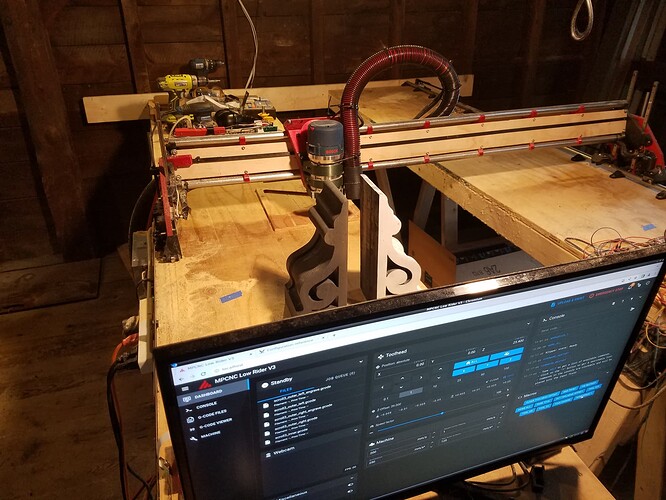

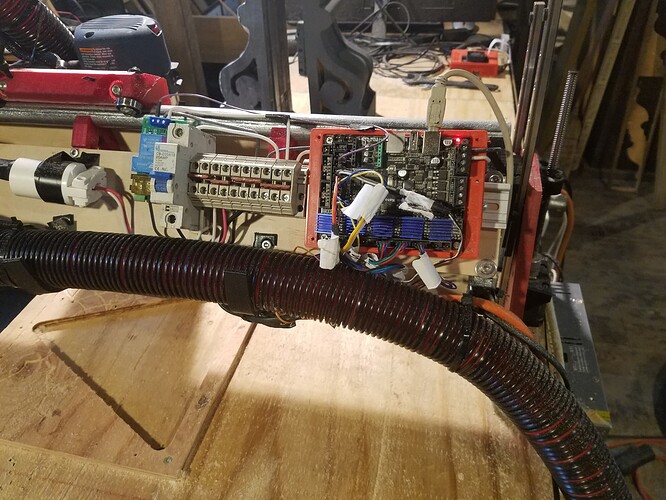

For what its worth, here’s the klipper printer.cfg I work with for the lr3. The klipper SET_SKEW function is invoked following home of the axis, which enables precise squaring of the work area.

The spindle is switched on/off with a relay so the TOOL_ON/OFF macros can be embedded in the gcode. The emergency stop procedure also switches off the spindle a split second before it slams onto the table.

[include mainsail.cfg]

# This file contains common pin mappings for MKS Robin Nano V3

# boards. To use this config, the firmware should be compiled for the

# stm32f407. When running "make menuconfig", select the 48KiB

# bootloader, and enable "USB for communication".

# The "make flash" command does not work on the MKS Robin. Instead,

# after running "make", copy the generated "out/klipper.bin" file to a

# file named "Robin_nano_v3.bin" on an SD card and then restart the

# MKS Robin with that SD card.

# See docs/Config_Reference.md for a description of parameters.

[stepper_x]

step_pin: PE3

dir_pin: PE2

enable_pin: !PE4

microsteps: 64

rotation_distance: 32

endstop_pin: PA15

position_endstop: 0

position_min: 0

position_max: 1660

homing_speed: 50

[tmc2209 stepper_x]

uart_pin: PD5

run_current: 0.95

[stepper_y]

step_pin: PE0

dir_pin: !PB9

enable_pin: !PE1

microsteps: 64

rotation_distance: 32

endstop_pin: PD2

position_endstop: 0

position_min: -2

position_max: 2743

homing_speed: 50

[tmc2209 stepper_y]

uart_pin: PD7

run_current: 0.95

[stepper_z]

step_pin: PB5

dir_pin: PB4

enable_pin: !PB8

microsteps: 64

rotation_distance: 8

endstop_pin: PC8

position_min:-5

position_max: 76

position_endstop: 70

homing_positive_dir: true

[tmc2209 stepper_z]

uart_pin: PD4

run_current: 0.95

[stepper_z1]

step_pin: PD6

dir_pin: PD3

enable_pin: !PB3

microsteps: 64

rotation_distance: 8

endstop_pin: PC4

[tmc2209 stepper_z1]

uart_pin: PD9

run_current: 0.95

[stepper_y1]

step_pin: PD15

dir_pin: PA1

enable_pin: !PA3

microsteps: 64

rotation_distance: 32

endstop_pin: PA13

[tmc2209 stepper_y1]

uart_pin: PD8

run_current: 0.95

[output_pin tool_power]

# tool_power pin PA4 is located at J52, the 6th jumper down in the endstop block

pin: PA4

value: 0

shutdown_value: 0

pwm: false

[output_pin tool_power_led]

# tool_power led pin PC14 is located at fan1 led

pin: PC14

[mcu]

serial: /dev/serial/by-id/usb-Klipper_stm32f407xx_12345-if00

[printer]

kinematics: cartesian

max_velocity: 200

max_accel: 250

max_accel_to_decel: 125

max_z_velocity: 25

max_z_accel: 50

square_corner_velocity: 1

[gcode_arcs]

resolution: 0.05

[pause_resume]

recover_velocity: 50.

[skew_correction]

[display_status]

[board_pins]

aliases:

# EXP1 header

EXP1_1=PC5, EXP1_3=PD13, EXP1_5=PE14, EXP1_7=PD11, EXP1_9=<GND>,

EXP1_2=PE13, EXP1_4=PC6, EXP1_6=PE15, EXP1_8=PD10, EXP1_10=<5V>,

# EXP2 header

EXP2_1=PA6, EXP2_3=PE8, EXP2_5=PE11, EXP2_7=PE12, EXP2_9=<GND>,

EXP2_2=PA5, EXP2_4=PE10, EXP2_6=PA7, EXP2_8=<RST>, EXP2_10=<3.3v>

# Pins EXP2_1, EXP2_6, EXP2_2 are also MISO, MOSI, SCK of bus "ssp1"

# See the MKS Lcd Config path file for definitions of common LCD displays.

#--------------------------------

# MACROS

[gcode_macro SET_TOOLHEAD_OFFSET]

gcode:

{% set xo = printer.toolhead.position.x|float %}

{% set yo = printer.toolhead.position.y|float %}

{% set zo = printer.toolhead.position.z|float %}

SET_GCODE_OFFSET x={xo} y={yo} z={zo}

[gcode_macro CLEAR_TOOLHEAD_OFFSET]

gcode:

SET_GCODE_OFFSET x=0 y=0 z=0

[gcode_macro TOOL_ON]

gcode:

SET_PIN PIN=tool_power VALUE=1

SET_PIN PIN=tool_power_led VALUE=1

[gcode_macro TOOL_OFF]

gcode:

SET_PIN PIN=tool_power VALUE=0

SET_PIN PIN=tool_power_led VALUE=0

[gcode_macro HOME_ALL]

gcode:

G28 Z

G28 XY

SET_SKEW XY=1701.8,1700.6875,1200

[gcode_macro PARK_TOOL]

gcode:

{action_respond_info("*** REMINDER: switch off spindle manually ***")}

TOOL_OFF

CLEAR_TOOLHEAD_OFFSET

G0 Z65

G0 X40 Y50

G1 Z25

[gcode_macro FW_RESTART]

gcode:

FIRMWARE_RESTART

[gcode_macro WORKSPACE_1]

# Configured for 25.4mm stock height, 9mm spoilboard height, 6in stock width

gcode:

SET_GCODE_OFFSET x=0 y=0 z=0

g0 z68

g0 x322 y315

g0 z64.4

SET_GCODE_OFFSET x=322 y=315 z=39

[gcode_macro TOOLCHANGE]

gcode:

g0 z36

g0 x-40 y-40

[gcode_macro TOOL_Z0]

gcode:

g0 z36

g0 x-40 y10

g0 z0

I also needed to edit mainsail.cfg to remove checks for hotend thermistor temperature within range before starting print job:

# Mainsail klipper definitions

#

# Copyright (C) 2021 Alex Zellner <alexander.zellner@googlemail.com>

#

# This file may be distributed under the terms of the GNU GPLv3 license

#

# Version 1.11

# add [include mainsail.cfg] to your printer.cfg to include it to your printer.cfg

# modify x_park, y_park, z_park_delta and extrude value at the macro _TOOLHEAD_PARK_PAUSE_CANCEL if needed

# use variable_park: False at CANCEL_PRINT to disallow the parking move

[virtual_sdcard]

path: /var/print

#on_error_gcode: CANCEL_PRINT

[pause_resume]

[display_status]

[gcode_macro CANCEL_PRINT]

description: Cancel the actual running print

rename_existing: CANCEL_PRINT_BASE

variable_park: True

gcode:

{action_respond_info("CANCEL_PRINT")}

## Move head and retract only if not already in the pause state and park set to true

{% if printer.pause_resume.is_paused|lower == 'false' and park|lower == 'true'%}

_TOOLHEAD_PARK_PAUSE_CANCEL

{% endif %}

#TURN_OFF_HEATERS

M106 S0

{action_respond_info("Calling cancel print base")}

CANCEL_PRINT_BASE

[gcode_macro PAUSE]

description: Pause the actual running print

rename_existing: PAUSE_BASE

gcode:

PAUSE_BASE

_TOOLHEAD_PARK_PAUSE_CANCEL

[gcode_macro RESUME]

description: Resume the actual running print

rename_existing: RESUME_BASE

gcode:

##### read extrude from _TOOLHEAD_PARK_PAUSE_CANCEL macro #####

#{% set extrude = printer['gcode_macro _TOOLHEAD_PARK_PAUSE_CANCEL'].extrude %}

#### get VELOCITY parameter if specified ####

{% if 'VELOCITY' in params|upper %}

{% set get_params = ('VELOCITY=' + params.VELOCITY) %}

{%else %}

{% set get_params = "" %}

{% endif %}

##### end of definitions #####

#{% if printer.extruder.can_extrude|lower == 'true' %}

# M83

# G1 E{extrude} F2100

# {% if printer.gcode_move.absolute_extrude |lower == 'true' %} M82 {% endif %}

#{% else %}

# {action_respond_info("Extruder not hot enough")}

#{% endif %}

RESUME_BASE {get_params}

[gcode_macro END_PRINT]

#rename_existing: END_PRINT_BASE

gcode:

{action_respond_info("END_PRINT")}

_TOOLHEAD_PARK_PAUSE_CANCEL

#Disable Steppers

M84 X Y

[gcode_macro _TOOLHEAD_PARK_PAUSE_CANCEL]

description: Helper: park toolhead used in PAUSE and CANCEL_PRINT

variable_extrude: 1.0

gcode:

{action_respond_info("_TOOLHEAD_PARK_PAUSE_CANCEL")}

##### set park positon for x and y #####

# default is your max posion from your printer.cfg

{% set x_park = printer.toolhead.axis_minimum.x|float + 5.0 %}

{% set y_park = printer.toolhead.axis_minimum.y|float + 5.0 %}

{% set z_park_delta = 2.0 %}

##### calculate save lift position #####

{% set max_z = printer.toolhead.axis_maximum.z|float %}

{% set z_safe = max_z - z_park_delta %}

#{% set act_z = printer.toolhead.position.z|float %}

#{% if act_z < (max_z - z_park_delta) %}

# {% set z_safe = z_park_delta %}

#{% else %}

# {% set z_safe = max_z - act_z %}

#{% endif %}

##### end of definitions #####

#{% if printer.extruder.can_extrude|lower == 'true' %}

# M83

# G1 E-{extrude} F2100

# {% if printer.gcode_move.absolute_extrude |lower == 'true' %} M82 {% endif %}

#{% else %}

# {action_respond_info("Extruder not hot enough")}

#{% endif %}

{% if "xyz" in printer.toolhead.homed_axes %}

{% set x_park = 101.0 %}

{% set y_park = 102.0 %}

{% set z_safe = 66.0 %}

{action_respond_info("Moving axis to safe positions")}

G90

G1 Z{z_safe} F900

G1 X{x_park} Y{y_park} F6000

{% if printer.gcode_move.absolute_coordinates|lower == 'false' %} G91 {% endif %}

{% else %}

{action_respond_info("Printer not homed")}

{% endif %}

{action_respond_info("_TOOLHEAD_PARK_PAUSE_CANCEL end")}

Pics, with examples of architectural parts made with the lr3: