Knipex?

https://www.amazon.com/Knipex-1262180-Adjusting-Insulation-Strippers/dp/B003B8WB5U

I’ve had good luck with that style but hadn’t seen any affordable - then again hadn’t looked lately and all that kind of stuff seems to be available way cheaper now!

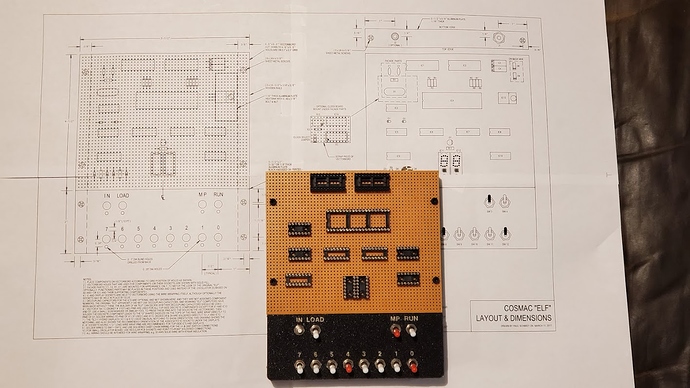

But neither of those will do 30awg and that’s what I was working with. I’ve actually been using a lot of 30awg lately working on a wire wrapping project…mostly because I always wanted to try wire wrapping but also because I always wanted an early 70’s era microcomputer trainer so decided to build one:

I need to get back to wiring it up…got distracted by a few other projects and haven’t got around to picking it back up in a few months.

Those may be the newer version of shat I used. They were old when I used them and that was 10 years ago.

I am not a big fan of the tools that pull the insulation off for me. Maybe I just need to try higher quality tools. These ones had the tool in between the grips, so they were more compact. That felt pretty effective.

My buddy found them:

https://www.verical.com/pd/c.k.-tools-hand-tools-&-accessories-330013-3272734

I quit using that style of crimper since the results were not consistent I found.

After watching this fellows YouTube video I got some IWISS IWS-2820M crimpers from Banggood and they work very well. You make one crimp at a time but you can see what you are doing. I start with the stripped wire part then do the plastic. It is really important to do the plastic part for strain relief. Soldering makes these way too brittle and I’ve found the crimps usually fail with much handling. I have done the little JST connectors as well as Dupont style and have great results.

Finally realized that I’m going to do enough of this in the next few decades that I should own a pair. Fought with it for an hour, watched your video twice, made 6 good crimps in a row. I didn’t even realize the die has a different shape halfway across. I thought it was a shadow.

Thanks, man. Thanks a lot.

My eyes are too bad, and my fingers too fat. I’ve tried about 70 crimps, gotten at best a couple dozen, but only 16 were in groups of four that I could use in the housings, the rest had to be cut off to keep from having super-janky loops of wire running into the connectors.

I’m thinking of ordering one of those two-stage crimpers, and just doing it that way. Maybe I’ll have better luck than the method I have now. “What method is that?” Mash the ends of the cheap-assed insulation crimps together enough that they will actually fit into the .25mm slot of the crimp tool, jam the wire into the connector, trying to keep the insulation away from the wire crimp. Then, wishing my wrists were double or triple jointed, jam the connector into the tool, hoping that I’ve got it in the correct distance, and that the wings of the connector will wrap around the wire, and not fly out. After I ratchet the damned thing down, I then have to carefully use the ends of the tool to try to even out the connector, as it’s no doubt squished out in one direction or another and won’t fit in the housing, not to mention it’s no longer straight. Then, when I go to ram it up into the housing, I pray that I actually got a good crimp on the insulation, because odds are, it won’t fit, and when I pull the connector back out, it’ll pull the wire out of the connector.

Then, after I’ve cut off another 4-5 inches of cable, I give up and swear to try again another day…

Eyes can really matter, and even make it seem like it is a problem with your hands. Getting some magnifying tools (either something you wear on your head, a big lense thing, or a USB microscope) can really help your finger precision.

Also, because I like to give you a hard time, you can try to increase the zoom on the shop page and just buy a wiring harness.

If you had only given your referral code link… Decided just the wiring kit (going individual, not series) wasn’t enough, so I tossed in a couple of .5mm nozzles (in anticipation of building a Primo at some point), an endmill pack and a sticker for good measure.

What wire thickness does the motors need? I have a hard time finding spools of wire in Norway. Is 26awg too thin??

I think thats about as thin as I’d go. 24AWG is better.

Dang… it’s hard finding proper wire in Norway, either its sold out or wrong dimensions. I found 0.14mm2 at a train model shop. Ordering from abroad gets quickly expensive because of shipping and taxes. Are there any good ebay/ali alternatives? They all seem to be silicone

I’m doing it the same way like Jeff. And yes its often quite hard to properly insert the cable into the tool and keep it in the right position while crimping…

But practicing makes the master!

This little fellow helps me stripping the wires:

Ooh, I found 24awg, but single stranded. What is the reasons against one strand? Difficult to solder?

Solid core. Don’t use that, it will work harden and break with all the movement.

Solid core will stiffen and break faster true… But it also doesn’t allow as much current to flow through. That’s because when electrons flow through a conductor they travel through the outer skin of the metal. Not through the center or the core. It is more accurate to say electrons travel along a conductor not through it. So with a single stranded conductor you have less surface area resulting in less flow. Aka higher resistance. This gets worse when a solid core conductor is moved and flexed a lot. It will gets cracks and wavy ripples where it bends. This will cause bottle neck like areas that will generate more heat and lead to an early breakdown.

At least that’s what ITT-Tech taught me a long time ago before they got shut down.

I may be wrong but I thought most Nema 17 steppers came with 22 awg stranded wires.

Thanks! You all are making very sense. I finally found some stranded 24awg at a Norwegian electrical retailer, so now I’m all sorted out.

I don’t think ANYONE ever told me that.

I really like this group!

Some guy at university who was an electrician before getting his CS degree talked about hysteresis or something, which is why not only are stranded cables better, but why you twist the pairs, and try not to have really tight kinks in the cables. And why you never, ever, leave loops of ethernet (specifically coax of any sort) coiled up on top of transformers or power distribution panels. About had a fit when we found 9-10 coils of thicknet on top of a building’s circuit box…

I think this is mainly true for high frequencies. At high frequencies it’s not like electrical current in the normal sense but electromagnetic waves that travel down the wire like an antenna.

For low frequencies, e.g. 60 Hz in the wall, the bulk of the conductor does transmit the current. This would also apply for stepper motors.

But the mechanical benefit is still enough reason to use stranded wire.