Personally don’t recall reading posts by folks using 0.8mm nozzles for LR parts, I don’t recall seeing posts of people being unhappy/happy with resulting fidelity of the prints, or whether tolerances were acceptable on the 0.8mm nozzle printed parts with captured nuts and such?

Me… Cura 5.4+, Ender 3, 0.6mm nozzle, 0.32mm layer height, recommended infill + 10%, 3 walls, regular PLA (not Matte which seems delaminate). Used https://teachingtechyt.github.io/calibration.html, lots of test prints to figure out extrusion esteps, dimension accuracy/skew in X, Y and Z.

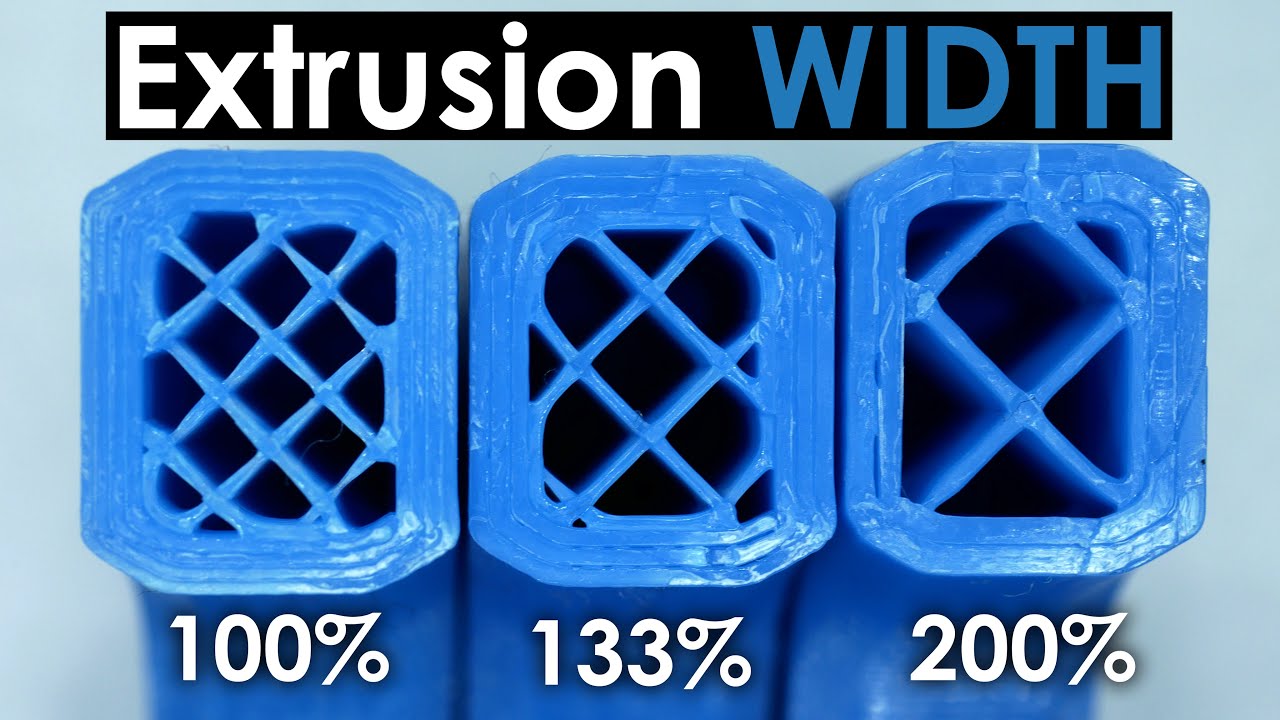

Printing LR parts (~15hrs for Core) was a great opportunity to learn and improve my 3D printing skills for parts where accuracy and strength matter. Got to learn bunch of stuff, like filament color/finish and extrusion width (separate from nozzle size) being a factor for part strength for example…

fwiw - My MP3DP klipper/printer.cfg and folder with Cura profile used to print more LR3 Cores (~10.5hrs) for my LR3 IDEX upgrade. Ender3 + LR3 were used to make MP3DP parts. MP3DP will make it’s own improved parts.

None of my machines are highly tuned. They could do more, faster if I invested more time learning, tinkering and tuning.