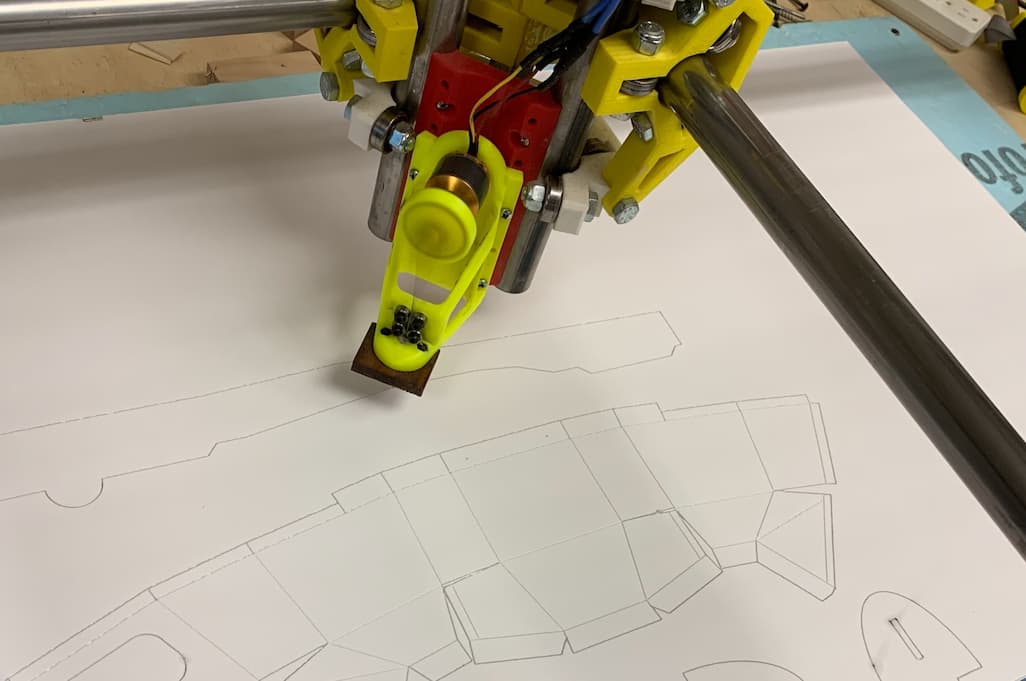

This is the setup that I have been using for several years and it works really well. I adapted the improved needle cutter to mount to the MPCNC. I used an old 12V DC power supply connected to the ESC to run the motor. I used a servo tester to control the speed of the motor.

I appreciate input, itsall helpful, but ultimately, it comes down to this…

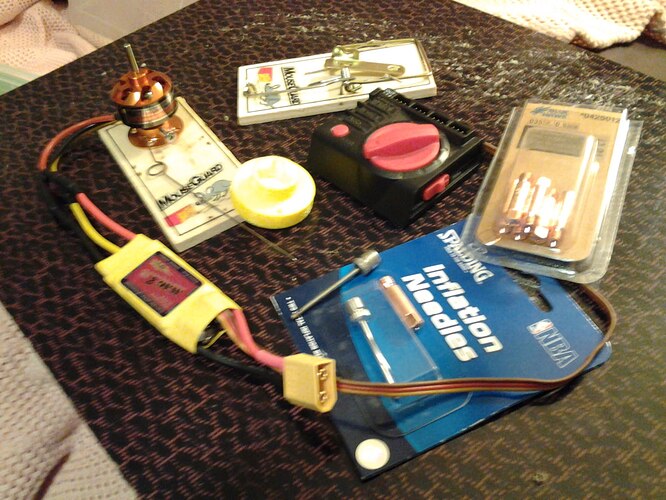

The brushless motor and speed controller with servo tester aren’t terribly expensive, but they’re not cheap either. A quick look at Amazon says about $45 for a bare minimum for all 3, waiting for some of it to ship from out of country.

Comparatively, I have the brushed motors and PWM controllers already, and even if I need to replace them, it’s $18, and here in 36 hours or less.

Some things I still need to buy. The music wire needle, MIG tip/guide, some misc hardware…

Then I need to adapt it to the LR3, so I am.still gping to have to re-do a bunch of CAD work anyhow. I might be able to use it with the Primo, I suppose, but I consider that to be a sub-par solution.

Anyway, I’m setting a cheapskate budget for this, and that extra $45 blows it. So I don’t mind doing the design work and CAD, when the goal is to use stuff that either I aready have, and is likely to be cheaply available. I realize that many people into the hobby probably have spare brushless motors and ESCs around, but I don’t have spares.

Does hobbyking.com have a canadian warehouse? You should be able to buy a whole quadcopter for $45.

The needle cutter’s philosophy from the beginning has been “use what you have on hand” and KISS…

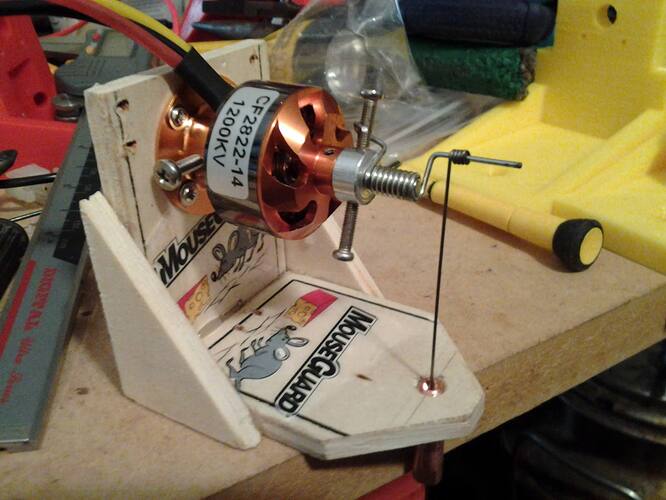

Here’s an early needle cutter using a salvaged DC motor from HP printer, a “flywheel with eccentric” of some sort, an athletic ball inflation needle for a bottom guide, and a short length of 0.025" music wire. The flexing of the needle is not really a problem… it’s spring steel and designed to… hmm, “spring”.

The “better mousetrap” needle-cutter in the video above uses almost every bit of a couple of cheap mousetraps – the wooden plate, springs, and bail – and actually got “straight line” motion. It’s not really practical but it’s cheap and may get your “creative juices” going.

Even if you have to get everything new… it shouldn’t be terribly expensive. Get Britt’s $18 motor/ESC and $7 servo tester, the music wire, and a card of MIG-tips or inflation needle from Walmart/HD/Lowes/etc… and a package of mousetraps from the “$1 store”.

My very earliest needle-cutter used an Intel CPU fan from a trashed PC and an inflation needle. Those fans were notoriously strong and would “bite” if you got too close while poking around inside. I used it to cut numerous planes and “miles” of bluecore fan-fold insulation foam before it died.

Useful stuff is all around you if you look hard enough. I’ll bet you’ve got most of what you need in your parts “stash/junkbox” already… and could build a dandy needle cutter. That’s half the fun of it IMO… making something useful out of junk/trash.

– David