The 60-in-1’s have trackball hookups  But you’re definitely on the right path with the Pi running Retropie. I was thinking of running a simular setup in my bartops, and lowboys, but honestly the 60-in-1’s, and all those ‘in-1’s’ with JAMMA sure does take a TON of work off ya. Plug and play really, once the harness is hooked all up. And the beautiful thing about JAMMA is, if you’re on ebay and see your favorite game PCB pop up on the cheap, it’s plug and play!

But you’re definitely on the right path with the Pi running Retropie. I was thinking of running a simular setup in my bartops, and lowboys, but honestly the 60-in-1’s, and all those ‘in-1’s’ with JAMMA sure does take a TON of work off ya. Plug and play really, once the harness is hooked all up. And the beautiful thing about JAMMA is, if you’re on ebay and see your favorite game PCB pop up on the cheap, it’s plug and play!

I had a retropi on the TV for a while. I forgot how violent my favorite video games were, but I noticed when trying to play with my kids.

I have been toying around with terraria. I think it would be pretty fun to play that on an arcade machine, although I am not sure how to aim…

Hmmm that would be tricky… But doable still! Maybe a light gun! haha

The only solution I could think of was a track ball

Ah yea, that’s not a bad solution tho. 1 You have a cnc machine to cut out the trackball slot under the control panel. Which to me was always the hardest part about trackballs. 2 I-Pac’s are cheap, and allow for easy wiring of a trackball, and all the other buttons. 3 you just gotta man. LOL

Some of those Japanese games are R rated too so I had to edit my list of games carefully when the kids were little.

Yeah the trackball router template was hard to make for my machine. Would be so much easier with a low rider.

We have an xbox stuffed in the arcade cabinet and play Terraria on it sometimes but it involves cheating and bringing out the wireless controllers.

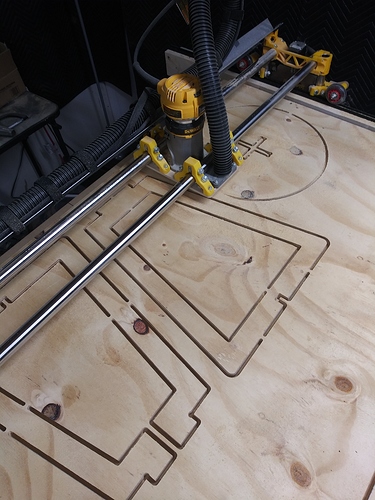

@tailslide @Paradox_Pete @jeffeb3 Well, it worked! You guys’s advice, and settings really helped, and I used the 1/4" 2 flute upcut bit! Got her real good in dirty today…

Before you fuss at me about those rails still being there, I’m gonna take them off tomorrow! lmao

Oh yea, she’s a real dirty girl! So is my shop now… LOL

Nothing special really, just some freebie DXF I got off the web, thinking it would be a perfect file to test with. My wife loves it and wants 8 more LOL Why did I have to start with something she’d like… Why…

1 hour 56 minutes with a 1/4" 2 flute upcut, @ 6mm DOC 9mm/s on the speed, .03 finishing pass.

What are you guys doing to keep the tubes clean of debris? I noticed mine kinda started getting a little jerky as it rolled over some dust towards the end. Didn’t effect the cut, but just made me curious.

Looks great! With the shop vac going my tubes just get a light amount of dust on them I try to remember to wipe once in awhile… sometimes the bearings get black gunk on them I have to wipe off… just one of those things you have to do.

I didn’t have my vac running much because my hose won’t arrive til tomorrow, but good to know! I’ll wipe 'em down before starting the next job. And then, I’ll have my vac running full time.