what about this power suplly 12v 2.0A for option number 1?

That PSU should work fine.

reading now about option number 2

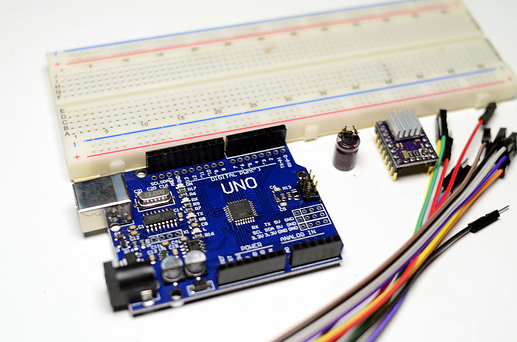

Here is a wiring diagram (and tutorial) for doing option 1:

The 12V would connect to the upper right side of the breadboard, and the left side is 5V from the arduino.

ok, i am reading that as well

This guide is exactly what you need for #1, actually. Take some time and read through that whole thing. Make sure you don’t burn up your Uno or the driver and you should have a pretty repeatable solution. They are even using the same stepper library I recommended, and they explain how to install it.

it going to be a long night… thanks for the info, hoping to have updates soon.

Yeah, you’re jumping in head first. It will be a steep curve to get started, but we can help if you need it.

It is also looks much harder than it actually is. I know I am on the other side of the learning curve, so I may be looking back with optimism, but most of the completely odd and seemingly impossible problems you’re going to find are usually pretty simple, and have very simple solutions. Share where you’re stuck, and we can probably fix them for you.

Good luck.

Good luck.

I am considering using Windshield Wiper Motor

Dear all,

I don’t want to be rude but you totally hijacked my buildthread of the MPCNC.

I would kindly ask to either create a seperate thread for whatever you want to adress or a moderator (@vicious1) might split this thread in half where appropriate and create a new one.

Thanks for your kind understanding.

Regards

Armin

Sorry! I didn’t scroll up enough to see who’s thread this was, I just saw the last few months were mostly from Atar. I think only Ryan can cut and move this.

First thread split and move I have done…easy!

Keep it simple!

A double crank slider or a double scotch yolk connected to the moving part in the center.

Normally I like simple, but ventilating people (or animals, since I am a veterinarian) is not so simple. In the case of covid19 doctors want to use PEEP , so pressure (and volume) have to be precisely regultated. So you have to think of a way to fine tune the movement of both sides, or make a system with a steppermotor for just 1 patient. In that way you can fine-tune in the software which I think would be easier to achieve.

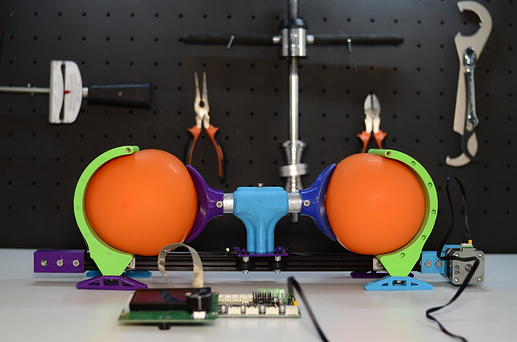

Great advice, thank you. in the configuration i presented there is an option for doing so by sliding the AMBU support (THE GREEN PART) on the rail - by doing so adjusting and regulate air pressure in a low-tech way. same way as human hand will operate to AMBU in field conditions.

I am still trying to figure out the electronics setup, which can be working the same way by changing the motor steps for each direction.

Thank you Ryan.

I have been reading all of the “I want to help with ventilators” projects but have not read that was something needed in the design.

Thank you for that important information!

visual update, starting from last

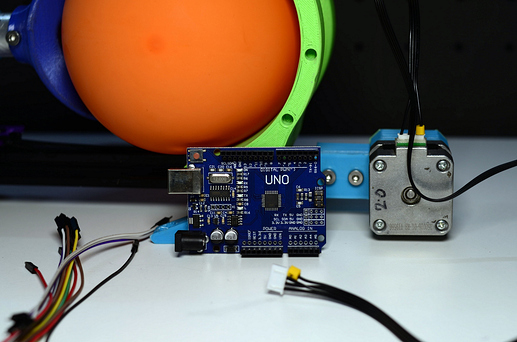

Took me all day to complete B.O.M for option 1 suggested by Jeff.

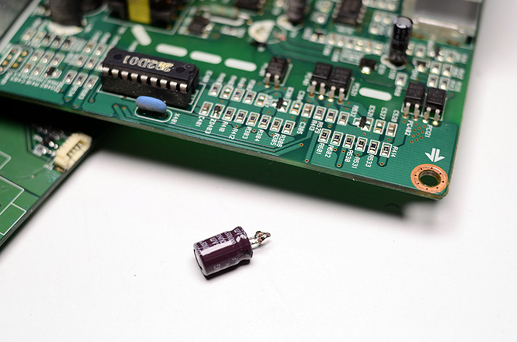

Harvested capacitor: found LG tv set in the trash, took it apart and desoldering capacitor i was looking for.

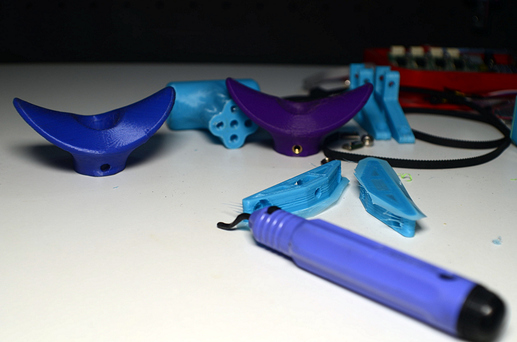

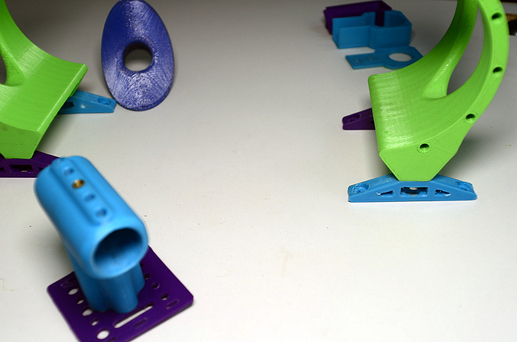

printed parts

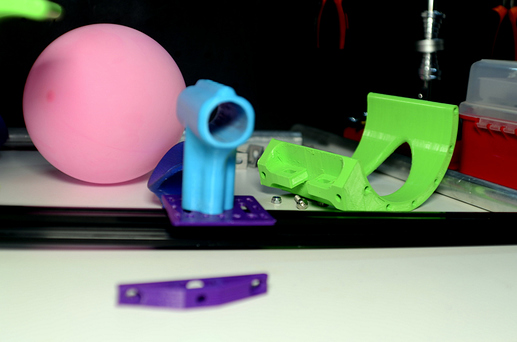

building process

tomorrow is wiring day!!

The sound of air (or half of it)