well we have good news and some half good and half not so good news

firstly though

Hi MakerJim, I’ve done some work in the aerospace industry also, I work across industries in general as a contractor but aerospace is where you get to do big crazy rigs, scary but fun

VOLUME DOWN!!!

here’s a wee vid of centrifugal compressor test rig I did 5 or 6 years ago, 2 big 3KW motors in series, one controlling speed, the other torque, a 2 to 1 gear box which then went to a CVT which ramped it up to anywhere in the realm of 30 to 60K rpm. Had to control pipe inlet and outlet valves and avoid choke conditions otherwise it would blow the compressor, possibly also blowing up the £1M CVT and we wouldnt want that now would we

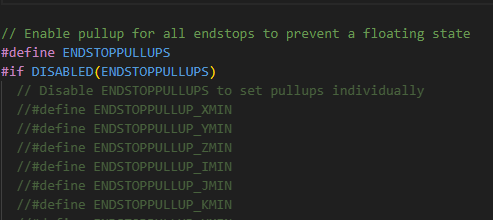

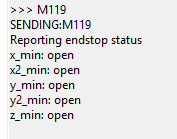

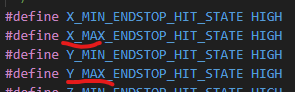

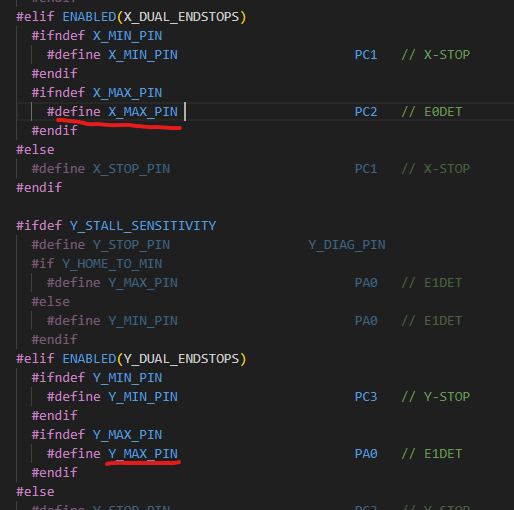

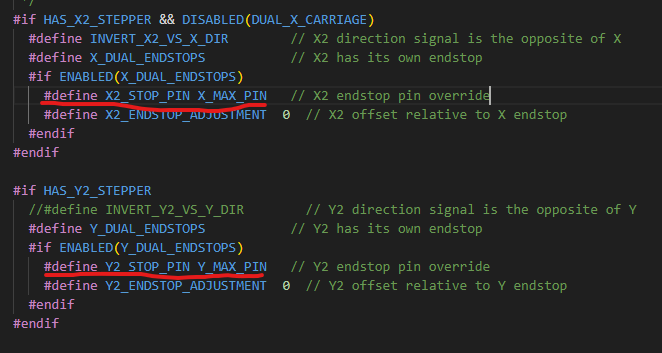

good news is the Marlin firmware seems to work in as far as I have tested it, axis motors all spin as they should and the correct endstops trigger as they should also. Need to get my belts all tightened up tonight and and get the gantry moving, then its a case of calibrating and then get it drawing on paper. Need to rig together the safety electronics also, E-Stop and contactors and such and then design and print a box to go under the table and then Thunderbirds are go!

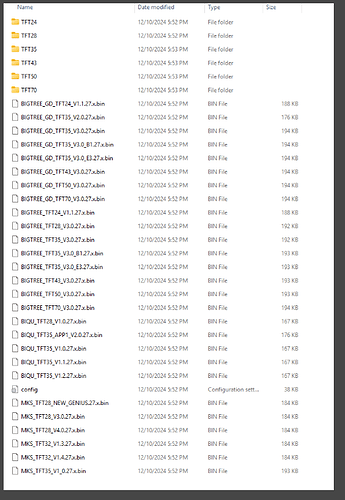

Now for the half good and half not so good news, the screen updated correctly and shows the V1 logo and all the menus seems spot on however I get the dreaded no printer attached message but only with the touch screen mode.

The half good news is that Marlin mode works nicely  I can move motors from there which is very encouraging, the only thing that tweaked my awareness is that steps/mm were set to 200, 200, 800 but I reset defaults and it went to 100, 100, 400 so thats me happy there.

I can move motors from there which is very encouraging, the only thing that tweaked my awareness is that steps/mm were set to 200, 200, 800 but I reset defaults and it went to 100, 100, 400 so thats me happy there.

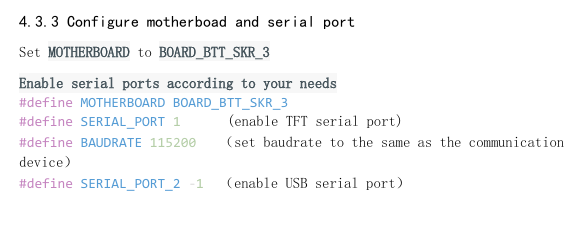

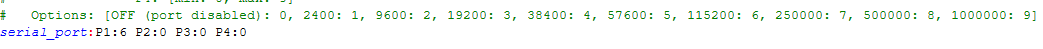

I checked the baudrate and set it to 115200 which is what the skr 3 TFT serial port is supposed to be set to

Wiring seems to be good because with just the TFT wires plugged in the screen only boots up with them in one orientation (wished they gave you the same connector on the board end of the cable instead of female headers)

I could live without the touchscreen but its a nice to have, any thoughts or ideas on where to start looking? Surely theres not anything board specific about the TFT config is there?