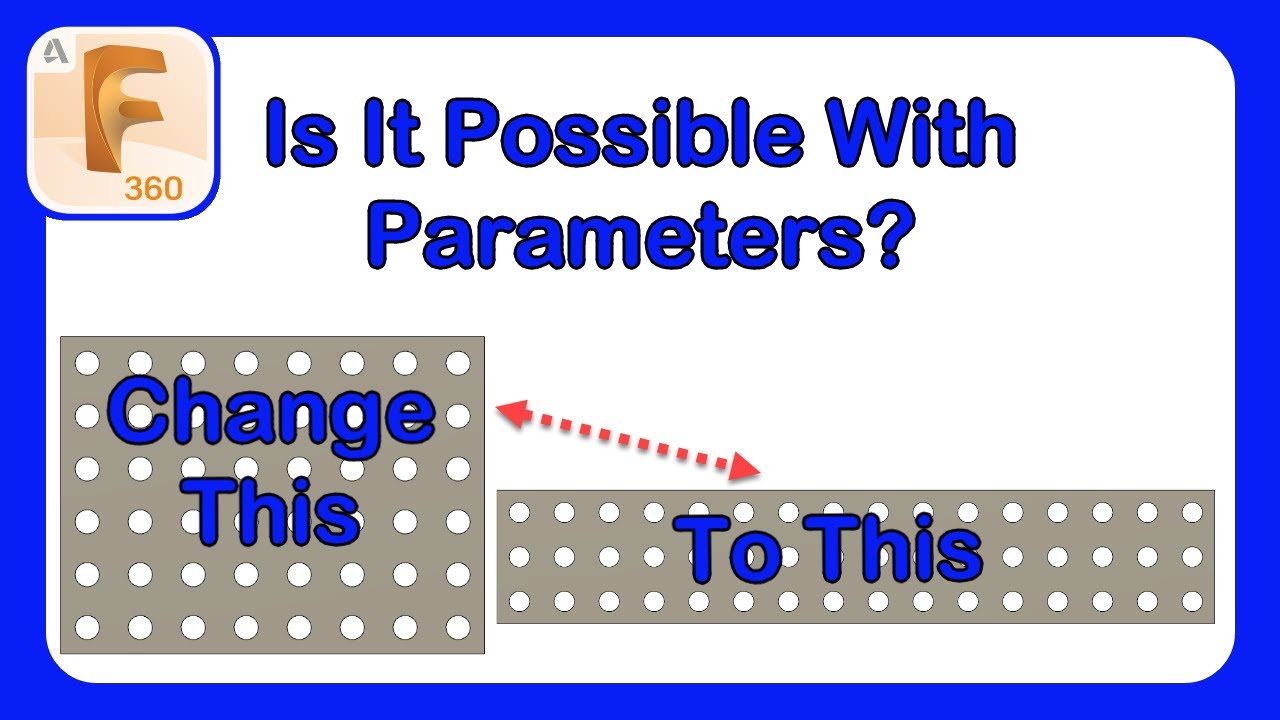

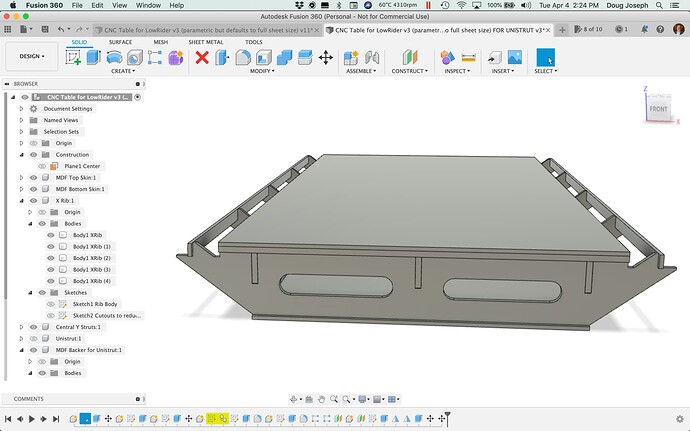

Please note that I dug into how to parameterize the quantity of ribs and struts, etc, so that they should change as needed if someone edits main cut width parameter or the main cut length parameter, etc.

Not sure what you did, but usually how I do that is to use a rectangular pattern with the count set to something like 2+int(tableLength / 250mm) to have struts less than 250mm center to center. Then set the pattern length to tableLength - materialThickness and it should work out. It might have one more than you think it should for an even multiple of 250 but that’s why it’s less than 250mm center to center. I’d likely use a larger distance anyway…

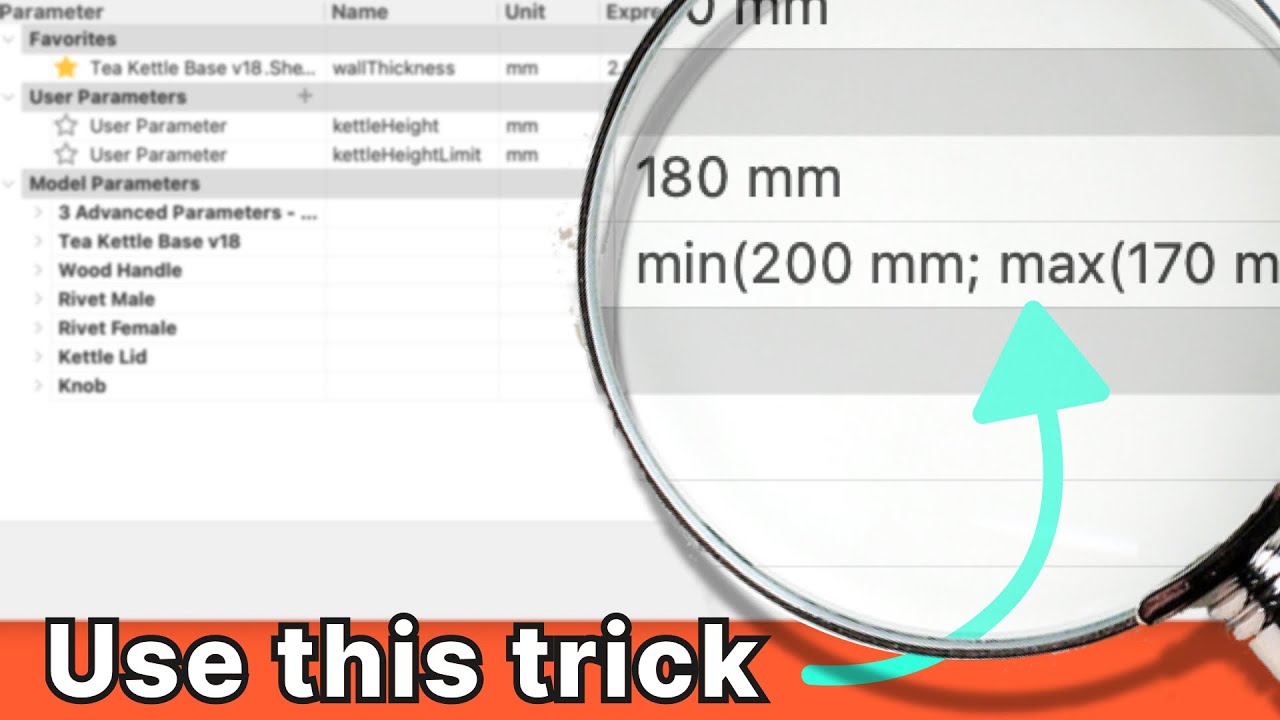

One little tidbit I had to find out, was that the params default to a unit, and for quantities of [ribs/struts/etc] the quantity param has to be unit-less. So if anyone is trying to do this, and Fusion 360 just won’t accept your quantity param, check the units. Also, I could not see a way to change a param with units to one that is unit-less. I just deleted the param and re-added it the right way.

Right. Which is why my calc has tableLength/250mm tableLength is a parameter in mm so dividing by a number of mm results in a unitless count.

@Ryan, despite what I said in a video I recorded several days ago, please don’t feel any pressure. It’s all a work in progress. I did finally get the video posted. Link up soon wherever is best place to post it.

EDIT: Ok, the video is now over here:

No Worries. My head is down until the machines ship out to Colorado. Keeping all the printers humming to stock the shelves. 4 days is longer than they have ever been off, I think. Hopefully Rmrrf nudges sales a bit higher to afford to get some help in for a handful of hours a week. I am so close. The first employee is just super expensive.

Then maybe I will get back on pre-covid track. If any of you remember, we were all headed to Mrrf, and I was super excited to hire someone when I got home. 2-3 weeks(?) before Mrrf lockdown started. Sales spiked and I couldn’t hire anyone then supply chain issues. I finally, just today, got 2 months worth of Skr’s ahead of inventory. I have been stuck 3 weeks behind or more for about a year straight.

I guess that is a long way of saying something is changing when I get back so I can spend time making more things (or finishing the details on the things I have started, at least), and get some more Forum time. Fell like I am never in here anymore.

I hear you! Thank you for all you do! From my perspective as a pastor, the Covid fallout was a nightmare. And for many, the fallout is still happening. Some key decisions about how to approach it made the “cure” worse than the disease.

Doesn’t feel like it, you answer everyone with absolute patience and are always present.

As teachers we learn that kids have to have the feeling of being supervised in the breaks. That’s what you absolutely achieve here. Omnipresent Ryan. ![]()

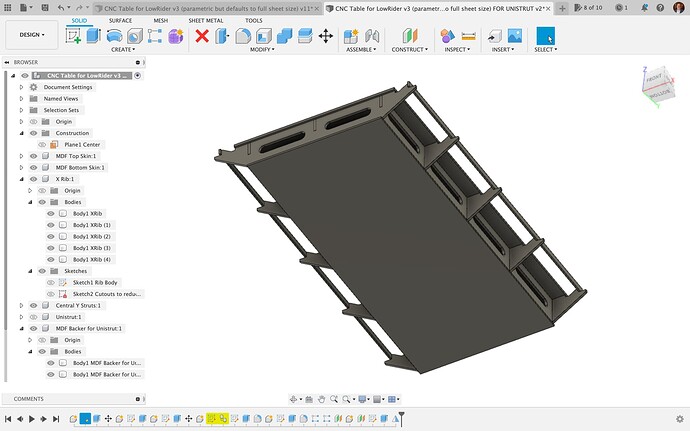

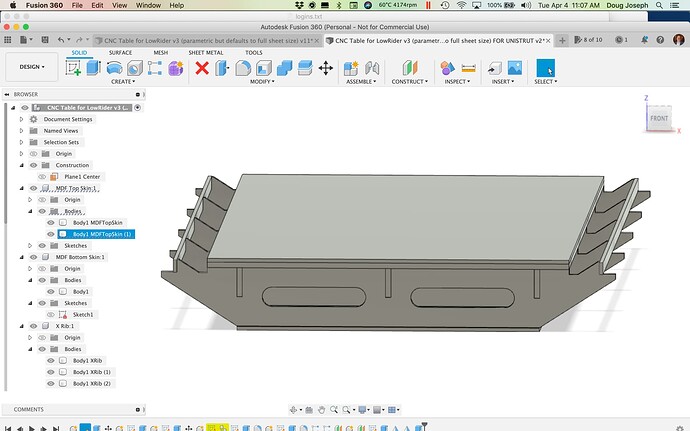

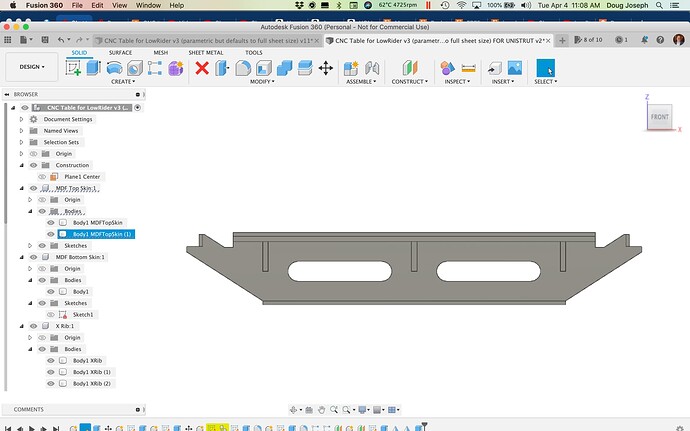

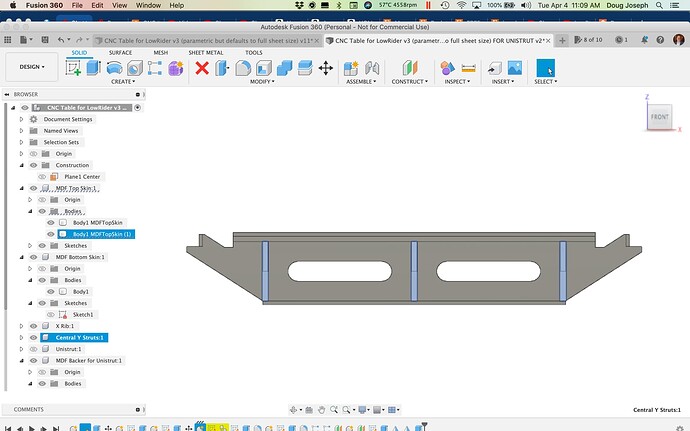

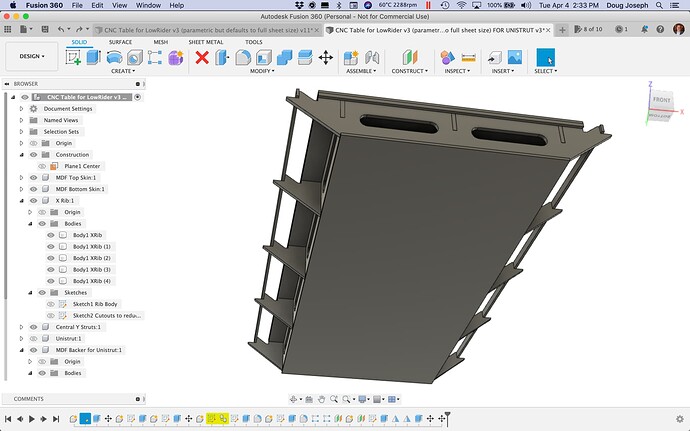

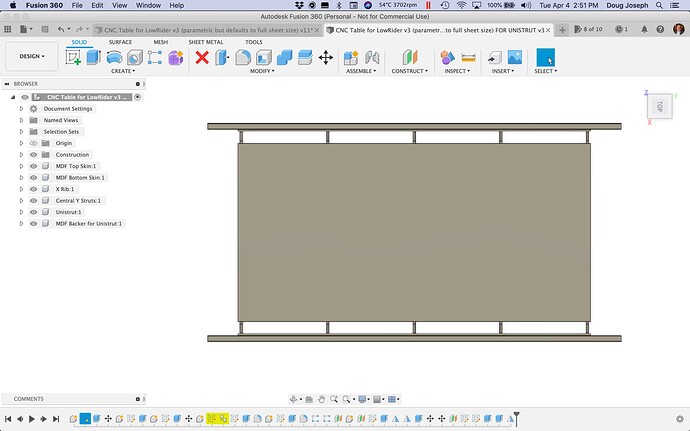

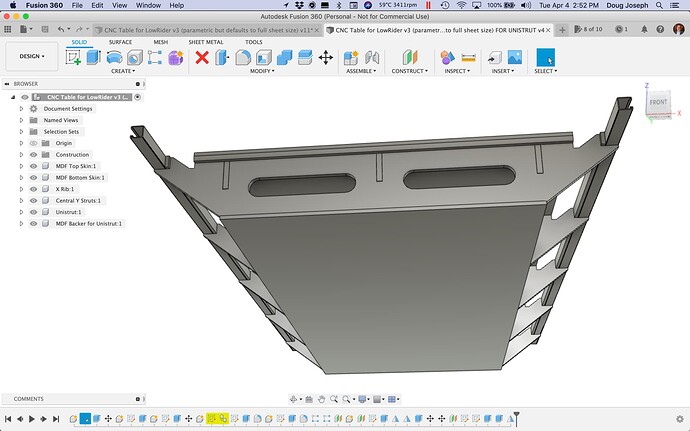

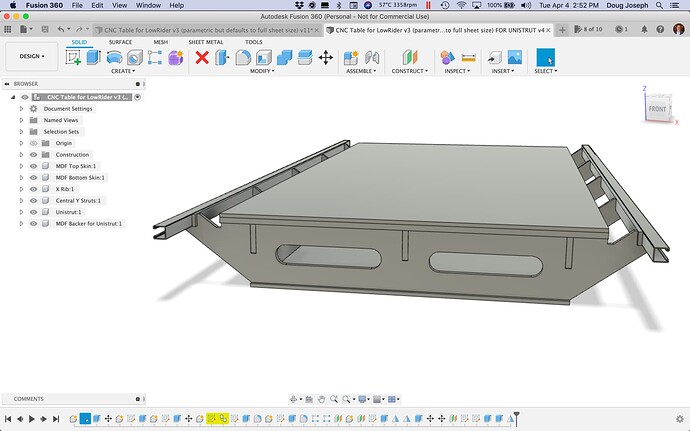

OK, so I mentioned above that I had intention of creating a version made for metal struts (aka Unistrut, aka Superstrut). Well, I have that version just about ready to go. See screen shots. This would get around the issues of having to scab together some type of wood long enough for the sides that the LowRider rides on.

Regardless, I welcome input and help on how to design the legs / support structure for the table. 4 legs are easy, but they would require some form of leveling. Casters are desirable, and there are heavy duty casters that also do auto leveling (transition from movable to immovable) and they are affordable (for instance on VEVOR website). So four legs is an option. There is also a method of doing 3 legs, and a method of doing two legs and a pivoting two-leg prong that accomplishes “three point” blended with “four point.” Thoughts?

Also the thought occurs that it might be possible to do a version of this that accommodates drawers inside the torsion box cells. Thoughts?

From my swiveling armchair, I’d limit it to the four end-cap cells. Access to the side cells would be problematic under the best of circumstances. Granted, if you’re making it parametric, nobody has to add side-access drawers, but I think they are a phenomenally bad idea. I’d at least put off side-access drawers until later… Also, don’t forget that you need to keep some of the face frame intact to maintain the torsion box, so the drawers aren’t going to be overly large. Probably bit/collet/tool storage (maybe even some clever tilting mechanism for longer bits if you need it).

My thinking was to (if attempting it), keep lots of the face frame intact, with added secondary drawer mount faces added to the plan, so the torsion box would be largely unaffected. I agree it’s possibly a not-good idea, but I like to try to leave no stone unturned.

LOL ![]()

Another reason for sticking to just the end cells: Even if you weaken the torsion box, you’re only weakening it on the two ends, the inner partitions are still intact and providing full support. I’m guessing you probably still have plenty of strength, even if you open up those portholes into largish rectangles. Maybe double up the endcaps? Or reinforce the openings with an inner frame that acts like a glue block, but runs top and bottom the full width of the cell, and stringers on the sides. Then put in a couple of strips on the bottom for runners. If the drawers aren’t the full height of the openings (even by a smidge), it would be easy enough to put some guides into the back of the drawer to keep in in line, and even prevent pull-out (quiet, back there, we’re adults here!)

These concepts are inline with my ponderings on it.

See end of this post for links to view /download:

Table designed for metal struts:

…with mockups of metal struts added:

Click HERE for accessing the following…

DXFs for TABLE WITH WOOD SIDE RAILS:

-

21/32’’ plywood (Slot_Width 0.65625’’ or 16.66875mm)

-

23/32’’ plywood (Slot_Width 0.719’’ or 18.2562mm)

-

~.75’’ plywood (specifically Slot_Width 19.15mm, or 0.75393701’')

DXFs for TABLE WITH METAL STRUT SIDE RAILS:

I keep looking at that Superstrut, but at $82.20 CAD per side, (10’ length) it’s a pretty hard sell for me.

The half width size 13/16" size is a bit less, but still $67.20 CAD per side.

I did my original LR2 table using fir 2×4 rails that I could get which are nice and straight. Spendier than most dimensional lumber, but seemed to be worthwhile.

Finally found a store in driving range that I could get the Superstrut at, and it’s about twice the cost I had figured on. ![]()

It’s a shame they’re hitting you that hard for it up there. Here in our town, at the local Home Depot, I can buy a 10’ metal strut for $35.57 (US).

Sorry for butting in

But is some aluminum rectangle tubing a option ?

Or is the super strut something that has added features like the little trolly that fits inside ?