I have the NEJE A40640 laser module. There are a number of people on this forum using this module. This was my first module, but others who have upgraded to this laser were impressed. If all you to do is cut thinner materials like cardboard, then the NEJE A40630 might be a good choice. It is only a third the cost but is over half as powerful as the more expensive module.

The NEJE laser modules are plug-and-play with the Rambo board and recent V1 firmware, and I think the SKR Pro boards as well. Other control boards usually require a firmware update.

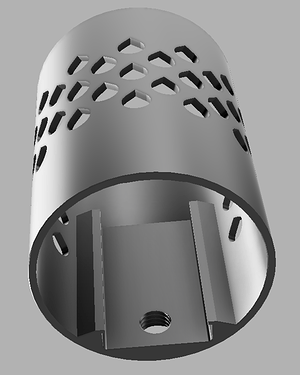

As for mounting, I wanted to be able to quickly switch between the laser and the router, so I designed a mount that fits inside the Primo Makita mount. I don’t know if this will fit the new LR3 or not.

A ZIP file of this mount can be found on this topic. I think the ZIP contains STEP as well as STL files. I don’t know if this mount will fit the new LR3 as is. If you want this mount, and it requires changes for the LR3, I’d be glad to work on it.

A couple of different people have done air assist nozzles for this laser as well.

When I purchased this module last September, it was the best one I could confirm. The specs for laser modules are a cesspool of lies, so it is hard to sort out “best.”

Since last September I’ve spotted a couple of other interesting modules. One has similar optical power to the NEJE, but it focuses to a smaller point, making the cutting power greater. And in the last week, I spotted a laser with four beams (the NEJE A40640 has two beams).