Which MMU version did you get? Too me it seems like the 2s has improved many of the quirks.

My friend has the 2nd on order but I haven’t spoke to him in a few weeks so I do not know the order status.

He might also do the Primo after seeing my MPCNC.

I agree the MMU has been relatively frustrating. This is by far the biggest print I have done and did hit 10 or so load errors, but I have gotten better at clearing them and not losing the print. Part of that is the hardware and software upgrades from Prusa and part is me reading their documentation.

I have the 2s.

Honestly most of the issues seem to be related to the filament sensor in the extruder and ‘s’ changes to it more than the MMU itself. Though I didn’t have an MMU before the s so it’s hard to say for sure…but that’s where I’ve had the biggest issues. Getting the sensor setup just right proved to be extremely tricky.

The other big thing that helped was replacing the PTFE tube retainer on the back of the MMU with one that uses quick release festo fittings. That both retains the tubes better without risking crushing them - and makes clearing misloads MUCH easier. It doesn’t prevent misloads…but clearing is a lot quicker and less annoying.

This little upgrade here:

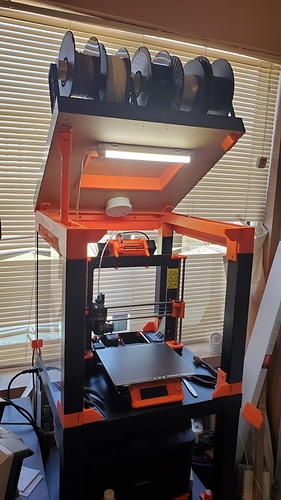

The other big issue is that the MMU takes up a LOT of space due to the buffer. I used the lack table printable enclosure so I can mount my spools up top and that makes it more compact…but having the machine in an enclosure also makes working on it (i.e. clearing misloads/misunloads) a lot harder.

Lately it seems I finally got my filament sensor happy so I haven’t had any load issues in a long time…but I still frequently get unload jams which are really tough to clear and almost impossible to clear mid-print. The issue is when the filament is retracted it forms a hook or a ball on the end instead of a nice cone - that then gets hung up in the drive gears and won’t let it unload. So the drive gears in the MMU wind up grinding the filament back there because it’s jammed in the extruder drive gear. I have to then open the extruder, cut off the blob or hook and cut out a foot or two of filament to get rid of the ground section back in the MMU…then reload it…but since it’s still trying to unload it won’t let me reload so I usually wind up having to reset the machine to clear it. Sometimes the firmware will let me successfully unload and reload after a jam…but it seems to be the exception rather than the rule (and yes I’m on the latest firmware.)

That’s why filament choice with the MMU becomes so critical. Higher quality filaments like Atomic and Prusament tend to retract/unload much more reliably. Hatchbox is a bit hit or miss since it sometimes gets that misformed tip, inland is unusable with the MMU because it’s softer and tends to just get ground in the MMU if there’s any resistance. This roll of marble hatchbox has been annoying because it gets brittle and then snaps in the buffer between prints so I have to unload the broken bits and then re-load it. It doesn’t fail in a print…just when it sits between prints it makes for more work and kind of defeats the point of being able to keep multiple filaments ready to go.

When it works…it’s brilliant (other than the wipe towers often using more material than the prints, but that’s hard to avoid due to the physics) but when it fails it can be a major pain to deal with. If I had room to lay it out instead of having to use the stacked enclosure setup it would be a lot easier to deal with and clear issues. But that’s a LOT of space which I just don’t have.

I I always thought the breaking while sitters die to moisture being absorbed by the filament so I never let mine sit o red at the very least cover it to reduce the contact

New filament is definitely better, but still jams and gets the blobs on the end. It seems to help a little to increase the retraction moves, but is not perfect.

I have gotten a lot better at clearing this mid print. I unscrew the PTFE holder from the MMU2S unit to expose the filament. Pull it forward if I can to cut away the part the gears ground down and then hit the right most MMU button which will back it out and reload it or switch to the next color depending on if it was a load or an unload jam.

Also, posted the modified files as a primo remix to save others time with Meshmixer.

https://www.prusaprinters.org/prints/36746-mmu-files-for-mpcnc-primo-254

Filaments vary. I live in the desert, very low humidity here. I’ve left spools of Nylon out for 6 months and still been able to print with them without any moisture problems.

Just some filaments seem worse than others about going brittle…and those that do I’ve found that the parts printed from them tend to be brittle as well. When I was initially printing my MPCNC I had a roll of black esun that amazon sent me by mistake (I had ordered hatchbox) and it was terrible. Fresh from the sealed vac bag it wouldn’t stick to anything, warped worse than ABS, and after very print 6-8" of filament above the extruder would become brittle and just snap. All of the parts I printed in it also developed issues. I had several crack across layer lines (not with the layers, across them) while just sitting on my desk under no stress. I later found the datestamp and it was over a year old before it got to me…but I suspect there was more than just age wrong with that spool.

This hatchbox marble that’s acting brittle for me isn’t as bad. It doesn’t warp, and doesn’t have issues adhering to the bed…but it does break at random places. The other 4 spools of various PLA - most of which have been out longer than the marble - aren’t having any issues. So I highly doubt it’s environmental. Just seems to be an issue with some spools right from the manufacturer. It was a brand new color from hatchbox when I got it as well so while I couldn’t find a date code seems unlikely that it would have been sitting long as the color had just been released a few weeks before I got it. But based on my experience with that black esun that was such a nightmare…I just can’t trust any spool that gets like that anymore.

Yeah I like phoenix for that reason too 7% rep humidity here in wis 60 to 90% 2 days and its aproblem

It’s a little disheartening to hear about your struggles with the MMU. I was thinking it was such a great upgrade! Perhaps they’ll sort things out even further. Or perhaps European filament is better?? Who knows… the decision is naturally put on hold, thanks to the delay.

Thanks for your thorough review! I love the MK3s for it’s ease of use. Getting the MMU would definately increase the options, but also the worries…

Is it possible to lower the current so that the motor driving the filament skips steps before it grinds things up? I know neither is desirable, but with skipped steps you would eliminate the need to get to the ground-up area and cut down on the amount of discarded/wasted filament.

There are screws/springs to control the tension on the filament. Just a fine balance. Not sure about lowering the current. My experience is you can get it to work with some tuning (especially the pinda/finda sensors as someone else suggested).

Yeah, I 100% loved my MK3s with no reservations. It always amazed me at how amazing it was and well thought out every little thing on it seemed to be. I had a hard time justifying the price buying it - but once I had it and experienced it I was converted and felt the price was 100% worth it. My old printer I just didn’t trust enough to leave it unattended for more than a few hours and then only if I was in the house with it. The MK3 - I had no qualms about leaving it running and even on really tricky prints very very seldom had any kind of failures or issues.

Which is why I was so disappointed when I added the MMU and spent the next two months struggling to get it to work let alone be reliable. Firmware updates helped for sure…but it was still a big kick to go from a machine I trusted so much to one that I was almost scared to use because even single filament prints were resulting in jams and requiring me to spend time dealing with it.

The one big thing I learned is that it works best when there are minimal differences between the filaments you’re using with it. Yes, you can adjust the tension - but it’s got to be set in a way that works for all of the filaments. So if one (like inland) is unusually soft it may grind while other filaments may slip because they’re tougher. Eliminating my lower end filaments (which had worked just fine on the MK3s by itself) solved a lot of the problems. But I still occasionally run into a few.

I’d love to use Prusament all the time, I’m really impressed with their filament. But ordering direct is kind of a pain with shipping (and lead times) and stock on Amazon they still can’t keep up with. Right now I’m running 3 spools of hatchbox (Grey, black, white) and 2 spools of PETG and it’s been about 95% reliable. The big issues seem to come with mixing filament brands - even if you’re only doing a single color since it ejects the filament at the end of each print. So if you get a bad end in the retraction it will still jam and you’ll have to clear a jam.

If you stick with all one brand of good or high quality filament and don’t have to use the enclosure like I do…it’s probably a lot more enjoyable experience than I had.

I am glad that I got to use my Mk3 without it for a few months first though and learned just how great the machine is - if I had started with the MMU I would have had a far less positive overall opinion. But at least this way I learned it was mostly the MMU that frustrated me and the printer overall is outstanding.

Hopefully the MMU itself is available by that point. I just checked the other day and prusa is focusing on printers only until further notice…

I’m trying to figure out how to set up the Telegram Octoprint plugin to let me know when there is a filament change. I know that I can set a timer, but I never fully trust the timing of the slicers/printers/servers. If telegram can notify me when the user input is required, then I can even be out of reach from the WIFI. I don’t want to open up the octoPI towards the open internet, so a Telegram bot is a nice bridge to access it from afar.

So right now I’m trying to figure out how to use the “Pauseforuserevent” plugin together with the Telegram bot. I’ll let you know when I figure out - for me it would make the filament change without the MMU a liiittle more convenient.

I have octoslack configured and it is… great. I like to watch the first layer and skirt print, because if it prints fine, then I’ve passed 90% of my most common problems, but it is a few minutes into the print, so I added a line “M117 Printing” to that part of the starting gcode and octoslack can create a custom notification when that line is seen, and send me a slack message.

It also attaches a picture from the webcam and sends it to me when it’s finished, so I can be at the dinner table and get the “ding” and quickly check to see that it isn’t a disaster.

I used to do something similar with a push bullet plugin, but I don’t have pushbullet anymore.

I’m sorry for piggybacking your octoslack experience jeff… but, do you have any suggestions for how I can make the pause-for-user-event trigger a message in the telegram bot plugin???

I could easily ditch telegram for slack, I don’t use telegram for any other things than the plugin bot.

I don’t. I looked at their home page, and I don’t see a lot of the options that octoslack has. Octoslack supports a bunch of protocols, but not telegram (as far as I can tell).

Octoslack says it supports triggering on messages from the printer, and specifically calls out filament runout messages.

Slack would be way overkill (and quite annoying) if you didn’t already use it. We have a free slack plan for our house, and I use it for things like IoT stuff around the house, and me and my wife use it to keep topics in channels (we have one for parenting, one for random links, one for financial stuff, one for planning events, one for source code/hobby topics, etc.). It is similar to discord.

If you just wanted a service for this particular function, I would guess octoslack and pushbullet would be near the ideal. You would install push bullet on your phone (they have a premium plan, but the free one should work for this) and then sign up on your desktop to get your api key and give that to octoslack.

Thanks a lot! I’m trying the telegram+pauseforuserevent trail for a while longer. If I can’t make it work, I’ll try the octoslack+pushbullet solution, it seems like a good alternative. Slack seems like too complicated for this specific task indeed. Strange no one has made a specific plugin for this, it seems like something that more people would appreciate?

Nice. I’ve used the MMU to print my Kids Wild Kratts creature power discs that are similar. Animal image instead of a letters. They are obsessed.

Side note. One of My best friends lives in Tromso. Small world. Worked with him for years in the US, but moved back a decade ago to be closer to his family. Need to visit someday (in the summer)