hi, i was looking for something like this. do you happen to have the drawing so i can reproduce it? thanks

So I ended up bailing on this particular upgrade. I wasn’t confident that it was going to be worth the effort, especially since it was kind of a sketchy design to begin with.

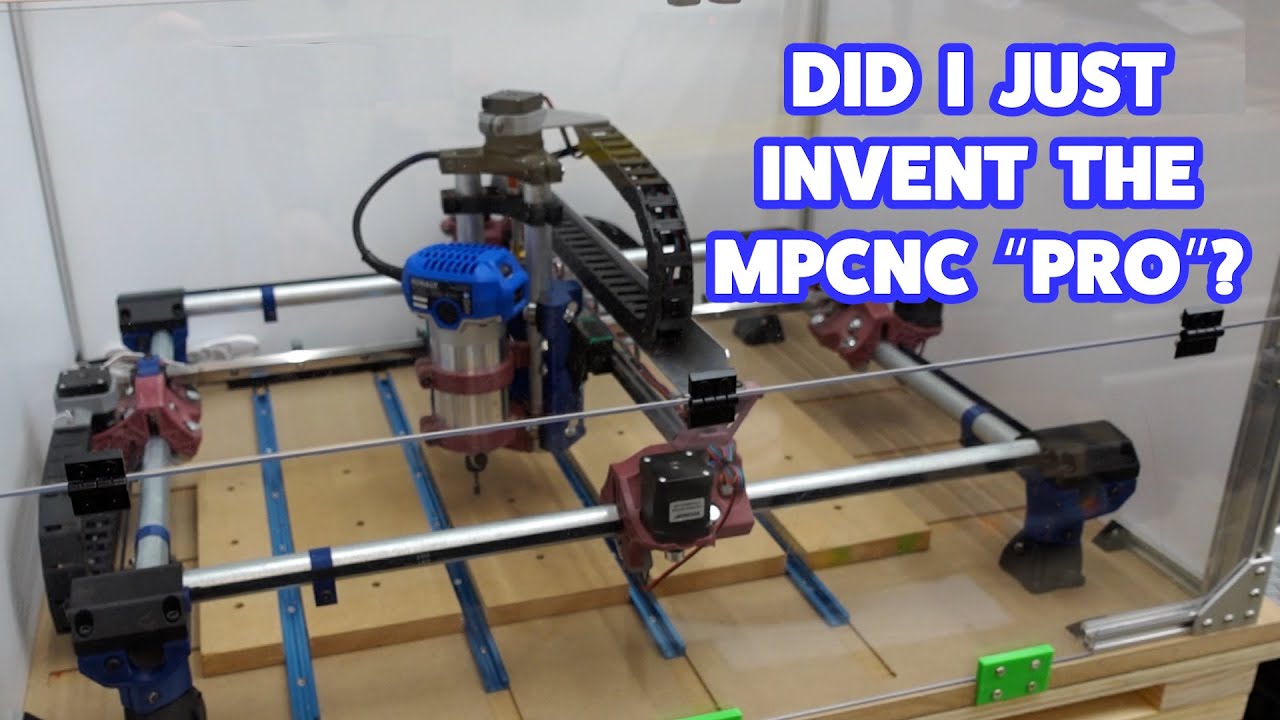

Since then I did a bunch of upgrades and made a video about it here:

I have been cutting aluminum very reliably since then. The one time I started to see things degrade, all I needed to do was tighten the router clamps…I guess there was some creep in the petg-cf over time.

I know linear rails are kind of blasphemous here ![]() , but they seemed like a worthy upgrade at the end (with the extra extrusion).

, but they seemed like a worthy upgrade at the end (with the extra extrusion).

As noted in some comments here, the z-backlash mod may not have been actually relevant. Yes there is backlash, but it’s not super relevant to this kind of short milling. I later found out that the bit I was using on aluminum had some friction welded aluminum on the tip, preventing it from drilling or digging reliably. After switching bits, most of my z-problems went away. It’s still nice to get rid of the backlash but not sure how much it helps the common use case.

Your video is what sparked my interest in building my MPCNC. Thank you for that.

It is helpful to hear that the z-backlash mod was not as relevant. I had planned on implementing it and even ordered extra lead screw and nut from Ryan. In the end I built it stock and have just kept them as spares. I have not noticed issues but I am working with wood not aluminum.

The weight of the router should remove the backlash in Z.

It doesn’t if you have some aluminum friction-welded to the tip of your endmill ![]() . I still ponder how it worked at all. It would still drill, but with a ton of effort and noise, and I guess it would eat up the backlash while it attempted to do so. That’s why I thought it was a problem – Whenever I tried to contour cut something, I had to make toolpaths at least 0.5mm deeper to get through it.

. I still ponder how it worked at all. It would still drill, but with a ton of effort and noise, and I guess it would eat up the backlash while it attempted to do so. That’s why I thought it was a problem – Whenever I tried to contour cut something, I had to make toolpaths at least 0.5mm deeper to get through it.

Related: I have now been through a few different endmills from Amazon, and both “Yonico” brand bits I have (1/4", single-flute carbide), get friction-welded aluminum stuck to them immediately. The similar SpeTool, bits have been wonderful . Two of them has like 20 hours milling only aluminum at my feeds and speeds with no lubricant (~22k RPM @ 600mm/min, 0.4mm DOC for contouring, 4mm DOC for adaptive/trochoidal @ 0.6mm stepover).