What depth of cut or Z step was your tool set at?

1mm step 4mm total… didn’t even touch the wood…started in the air even after homing z axis…

Can you post the gcode?

Maybe tonight if I get home at a reasonable time… had to get away from it last night before I adjusted it with a hammer… really starting to question if I should have built it… zero coding experience is hurting… can’t work out what I’m doing wrong in Estlcam… version 11 menus are a little different to what’s on V1 info pages…I even jumped on fusion360 and drew my tee nut hole and tried Estlcam with .dxf file and couldn’t work it out… feeling stupid and frustrated

No there is a steep learning curve. Once you get past the hurdle you will be fine.

If I need to redo the instructions I can. These things are hard for me to judge, they look the same to me as I have seen it evolve slowly. If you can be specific to where you are stuck maybe I can revamp it sooner rather than later.

You are working on the crown tutorial right?

I will remember your frustration and even more, those who are standing by and walking you through it.

I know my time will come - and I can’t thank you guys enough already, and thank-you Sean for sharing your problems.

- it makes me feel fantastic knowing I’m not alone

!

!

Not here your not alone help is always a keystroke away

Hang in there! Otherwise you’ll likely have people lined up at your door willing to ‘adopt’ your beautiful build!

I often wish Estlcam’s documentation was a little more complete but after a while, ‘learn by doing’ seems a viable plan. And don’t believe for a second you’re the only one who’s ever considered a hammer as an ‘adjustment’ tool ![]()

It’s likely that someone in these forums has either had and/or will know how to fix any issues you may run into and will be willing to help. Make some dry runs, cut some foam, hang in there and you’ll no doubt soon be posting pix to the “Things You’ve Made” forum. ![]()

I don’t like to help in private messages, and there are a lot of people that can help if they see you gcode file. Here is the first chunk:

M03 S24000

G00 Z5.0000

(No. 1 Linear pocket: Hole 1)

G00 X5.3557 Y3.2500

G00 Z0.5000

G01 Z0.0000 F3.000 S24000

G01 Z-1.0000

G01 X14.6443 F15.000

The good news is, you’ve just missed a couple of settings.

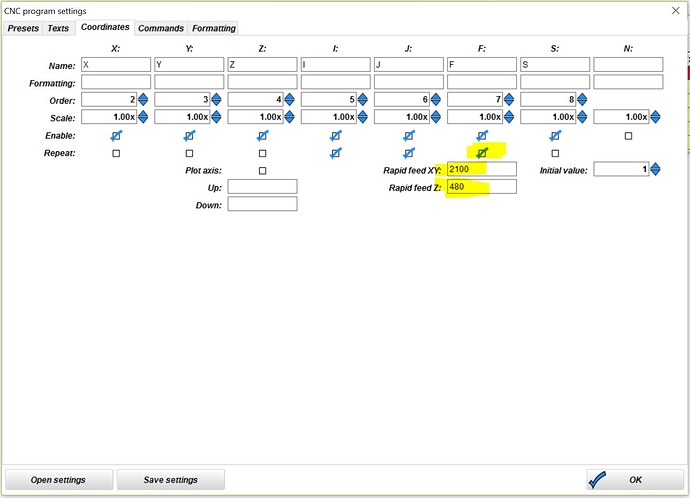

G01 Z0.0000 F3.000 S24000. the F3.0000 is in mm/min. The units in the gcode file always need to be in mm/min. So you’re going 60x slower that you asked for. This setting is in the estlcam basics dialogs.

G00 X5.3557 Y3.2500

G00 Z0.5000

These moves need to have speeds on them. I think there is either one setting for ‘speeds on every line’ or also one for ‘speeds on travel moves’. I don’t know the exact words.

You’re just missing a few check marks. The hammer isn’t needed.

ok i will have a look tomorrow, just gone midnight here… thanks so very much… true champion…

Cheers Jeffeb3, some how estlcam got changed to millimeters per second… not sure how it changed unless i did it by accident… either way i ran the same shape through just as a path in the air and it took 58 seconds… thank you again… now i just have to work out how to do multiple tool paths on top of each other to make the tee nut holes…

Make sure you also find the setting to put a speed on every line. If you don’t, it will just use the last speed. That can be problematic when you go from a quick XY move to a Z move (which needs to be slower).

Any idea where I would locate it?? Had a look but couldn’t find anything that looked right?

Yeah I have that box ticked, just about to screen shot it… wondering if some of these settings aren’t staying set after closing the program…