Yes- the same mount. NEMA-17 is a standard, even in China. I used 75W motors- there is also a 50W version that’s a little shorter and probably more than strong enough. The price difference is about $5, so I went with the bigger motors.

I put together as much info on the motors as I could find here: https://drmrehorst.blogspot.com/2020/04/ihsv-servomotor-information.html

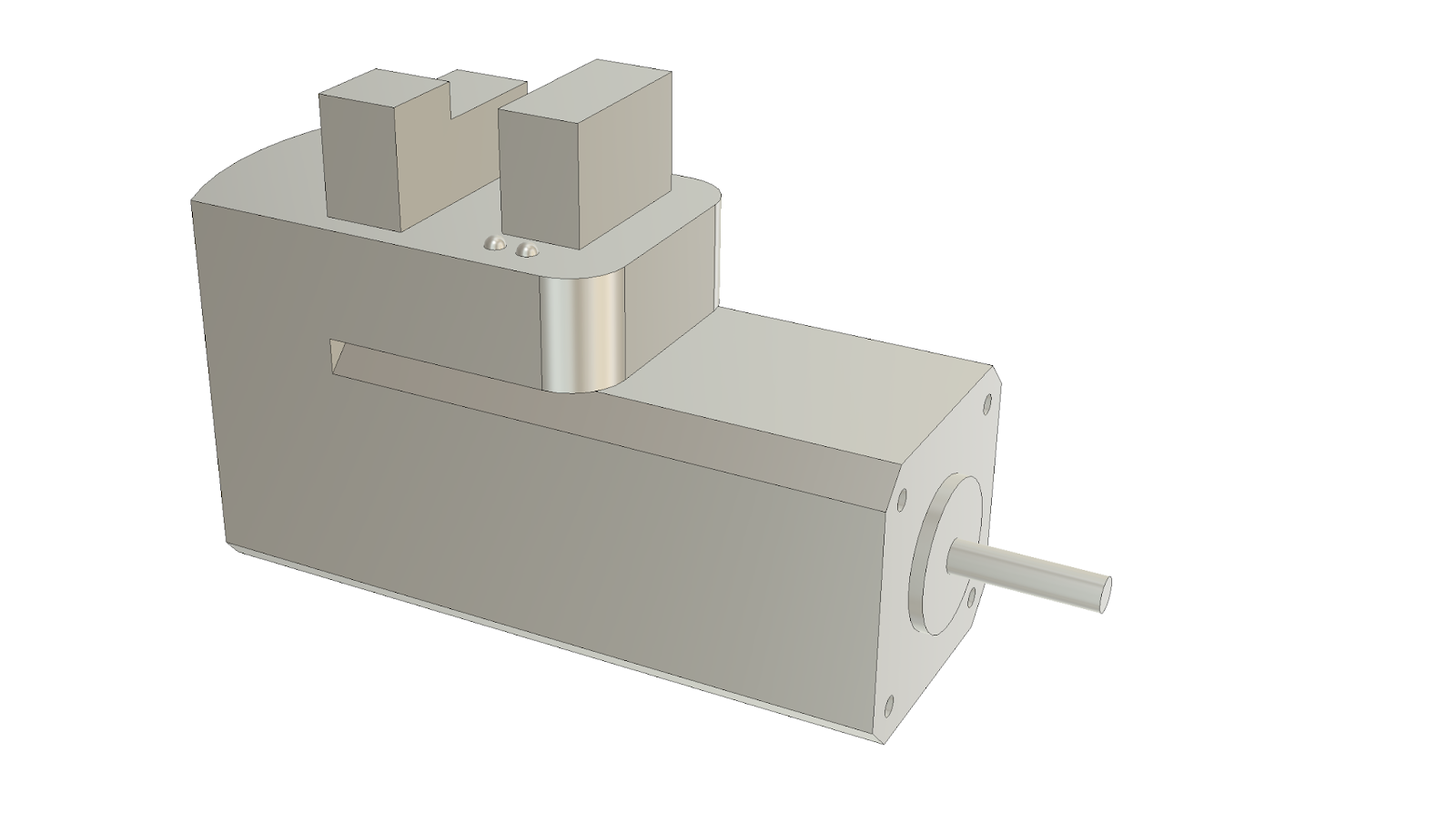

and a Fusion360 model is here: https://a360.co/2XSC0EP

I have not done any tweaking of any of the motor driver parameters- it’s just running with factory settings, so you may not need to get a USB to serial converter.

If you get a magnet like mine, be sure and put it in the table in the right orientation- with poles facing up and down. If you put it sideways it won’t work very well. You can tell which sides are the pole faces by sticking the ball to it. On the pole faces the ball will sit in the center of the face, and on the sides it will want to sit at the edges of the face.

I reshot the 2000 mm/sec erase video: https://vimeo.com/424381250

In my table, running at 2000 mm/sec is driving the motors at 3750 rpm. That exceeds their maximum speed spec (3k) which is a function of back EMF. I get occasional messages from the controller about over voltage condition - so running at that speed is playing with fire. I’ll be limiting the maximum speed to 1500 mm/sec to prevent problems. I used 16 tooth drive pulleys because I wanted to maximize the force available to drive the mechanism and didn’t know how the servos would behave. If I used larger pulleys on the motors it could easily run much faster, but at 1500 mm/sec it already throws the sand around too much to be useful. If you were going to use it for a plotter or light painting, etc., you could make it go a lot faster by using larger drive pulleys.